You want packaging that keeps your products safe and makes opening them fun. A mailer box supplier picks materials like corrugated cardboard and recycled fibers. These materials are strong, not too expensive, and good for the environment. Suppliers use new technology to design mailers that fit your product well. This helps cut down on waste. You get benefits from smart choices in packaging style, printing, and engineering. These choices can make shipping cheaper and make customers happier.

Key Takeaways

Mailer box suppliers use strong materials. These materials are eco-friendly. They use corrugated cardboard and recycled fibers. These help protect products. They also help reduce waste.

The manufacturing process has several steps. It includes cutting, folding, and assembly. These steps are done very carefully. This makes sturdy boxes. The boxes fit products well. They help save shipping costs.

You can change your mailer boxes. You can pick the size and shape. You can choose printing and finishes. This helps match your brand. It also makes unboxing special.

Suppliers check quality very strictly. They test how strong the boxes are. This makes sure your boxes protect products. It also makes sure they look professional.

Look for certifications like FSC and RCS. These show your supplier uses sustainable materials. They also show eco-friendly practices.

Pick a supplier with a good reputation. Make sure they have experience. They should be able to handle your order size. They should meet deadlines reliably.

Plan ahead for lead times. This is important during busy seasons. Talk clearly with your supplier. This helps avoid delays.

Work with your supplier’s design team. They help make packaging that fits your brand. The packaging protects your products. This makes customers happy.

1. Materials

Corrugated Cardboard

Most mailer boxes use corrugated cardboard. This material is strong and keeps products safe. It protects items from bumps and drops during shipping. Corrugated paper can handle heavy weight and absorbs shocks. You can count on it to keep things safe. Suppliers sometimes add gray board or chipboard for more support. These materials are cheaper and help protect your stuff. Cardboard boxes use paperboard, which is thick and easy to shape. This gives you packaging that fits well and looks nice.

Common materials used by mailer box suppliers:

Corrugated paper: strong, impact-resistant, ideal for shipping.

Gray board: provides structure, cost-effective, eco-friendly.

Chipboard: made from recycled fibers, flexible thickness, protects products.

Coated paper: offers high-quality printing and a smooth finish.

Kraft paper: tough, sustainable, and often chosen for eco-friendly packaging.

Tip: Pick corrugated cardboard if you want your products safe during shipping.

Recycled Content

Choosing mailer boxes with recycled content helps the planet. Chipboard is made from recycled fibers pressed together. This makes it strong and good for the environment. You see chipboard in subscription boxes and store displays. Its thickness can change, so you get the right strength. Most cardboard can be recycled, and over 80% stays strong after recycling. Using recycled materials means less trash and saves resources.

Chipboard keeps products safe and costs less.

Recycled paper and cardboard help lower pollution.

Compostable materials like plant-based papers break down fast and safely.

Sustainability

Picking sustainable materials helps the earth. Suppliers look for certifications like FSC and SFI. These show the paper comes from forests that are managed well. You might also see new materials like mushroom packaging and plant-based films. These break down naturally and do not hurt the planet. Kraft paper uses all types of wood and is made in a greener way.

Eco-friendly packaging is more than just recycling. You want materials that break down, can be used again, or use less energy and water. Suppliers try to get materials from nearby places to cut down on pollution from trucks. They also want their supply chains to be fair and open.

Note: Using sustainable materials helps the planet and shows customers you care.

It can be hard to find eco-friendly packaging. Sometimes, these materials cost more or are not easy to get. Suppliers have to think about price, protection, and design. More people want green options, but there is not always enough supply. You should ask your supplier about where they get their materials. Look for certifications to make sure you get the best for your business.

2. Manufacturing

When you order mailer boxes, you might wonder how suppliers turn raw materials into sturdy packaging. The manufacturing process uses both skilled workers and advanced machines. Each step ensures your boxes look good and protect your products.

Cutting

The first step in making mailer boxes is cutting the cardboard. Suppliers use large rolls of kraft paper and turn them into corrugated board. Machines like the MAKE-N-SHIP™ VPS100 cut the board to the right size. These machines use touch screens and smart software to make sure every box matches your needs. You get boxes that fit your products, which helps reduce waste and shipping costs.

Steps in the cutting process:

Prepare paper rolls with the right moisture.

Form the corrugated board by bonding liners and fluted paper.

Dry and trim the board to prevent warping.

Use die-cutting machines to shape the box and add fold lines.

Tip: Machines can cut many shapes and sizes, so you can get custom boxes for any product.

Folding

After cutting, the next step is folding. Machines crease the cardboard along fold lines. This makes it easy to bend the board into the right shape. You get sharp corners and straight edges, which help your boxes look professional.

Folding machines work fast and keep every box the same.

Some machines use rollers to press the folds, so the board does not crack.

Workers check the folds to make sure the box will close and open easily.

You can ask your supplier about the folding process if you want special shapes or extra-strong corners.

Assembly

The last step is assembly. Here, machines and workers put the boxes together. They use glue to hold the flaps and seams in place. This step gives your box its final shape and strength.

Assembly lines use both machines and people for quality control.

Glue or tape keeps the box strong during shipping.

Finished boxes get stacked and packed for delivery.

Note: Quality checks happen at every stage. Suppliers test boxes for strength and size, so you get reliable packaging every time.

When you know how mailer box suppliers cut, fold, and assemble your boxes, you can ask better questions and choose the right partner for your business.

3. Design

Customization

You can make your mailer boxes special in many ways. Suppliers let you pick the size and shape that fits your product. You can choose from different materials and finishes for your brand. Here are some ways you can customize your boxes:

Pick the box size you need, from small to big, so your items fit well.

Choose materials like classic white, kraft brown for a natural look, or bright white for a modern style.

Decide how thick the cardboard should be, like E-Flute for light things or B-Flute for heavy ones.

Add features like dust flaps, self-locking parts, or windows to show your product.

Ask for custom inserts to keep your products safe during shipping.

Print your design on the outside, inside, or both sides of the box.

Use recyclable and eco-friendly materials if you want to help the planet.

Try out your design with free online tools and see a 3D preview.

Order any amount you want, even just one box, with no minimum needed.

Get your boxes made quickly so you can ship on time.

Tip: Custom mailer boxes help your brand stand out and keep your products safe.

Printing

Printing changes how your mailer boxes look and feel. You can pick from different printing methods. Flexography is good for big orders and gives clear prints. Digital printing is great for small orders and detailed designs. Offset lithography makes sharp, high-quality images for large batches. You can add foil stamping for shiny parts or embossing for raised designs.

The paper you pick, like kraft or coated white, changes how colors look and how strong the box is. Some finishes, like UV or aqueous coatings, protect the print from smudges and scratches. These choices make your packaging look better and last longer.

Finishes

Finishes give your mailer boxes a special look. You can pick matte, satin, or glossy finishes to match your brand. Matte finishes look soft and modern. Glossy finishes make colors bright and shiny. Satin finishes feel smooth and have a little shine.

You can also use spot UV coating to make some parts stand out. Foil stamping adds a metallic look. Embossing and debossing add texture, so your logo or message pops out. These touches make your packaging look nice and help protect it from damage.

Note: The right finish can make opening your box a fun and memorable moment for your customers.

4. Quality

Inspection

You want every mailer box to be high quality. Suppliers use careful inspection steps to check each box. Here are the main things they look for:

Material Quality: They test the raw materials for strength. The cardboard must meet industry rules.

Design Accuracy: Workers use tools and computers to check size and shape. This makes sure your boxes fit your products.

Printing and Appearance: Inspectors look for clear prints and bright colors. They also check for smooth finishes and special touches like embossing or foil stamping.

Durability Testing: Boxes go through tests for strength. These include stacking, bursting, and edge crush tests.

Sustainability Checks: Suppliers make sure materials can be recycled. They also check that materials come from good sources.

Some factories use new technology for inspections. Automated systems and 3D scanning help find small mistakes. This keeps the quality high.

Tip: Ask your supplier about their inspection steps. This helps you avoid problems and get the packaging you need.

Durability

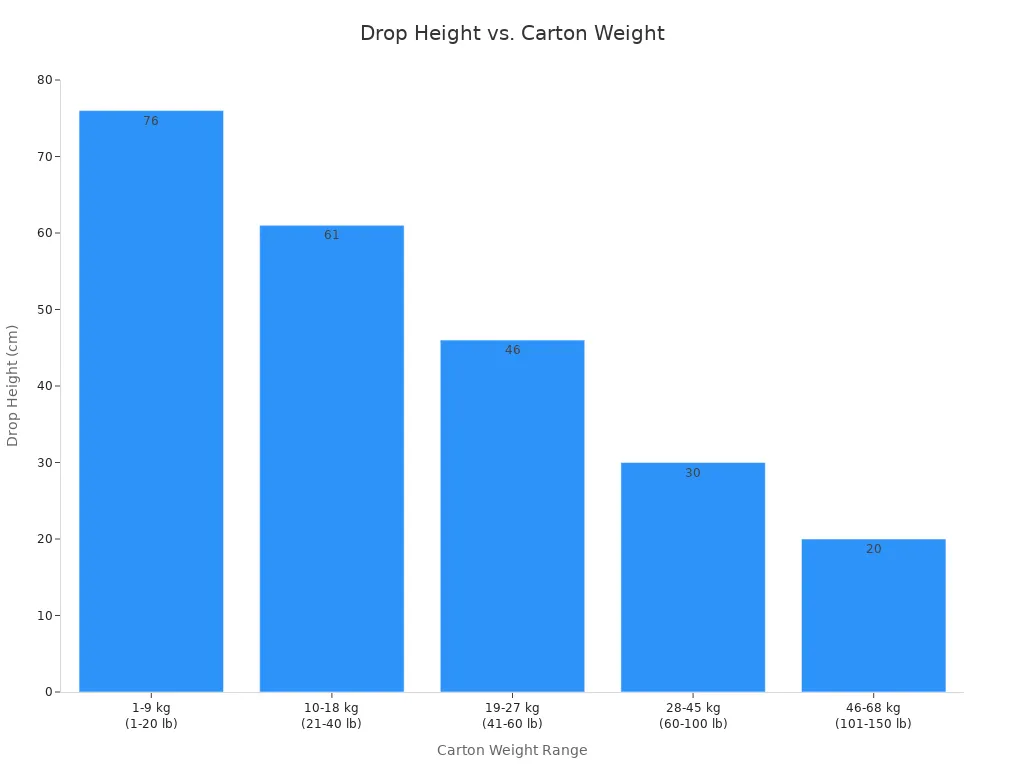

You need mailer boxes that keep your products safe. Suppliers test how strong boxes are with drop tests. They drop boxes from different heights, depending on the weight. This shows if the box and your items stay safe.

The steps are:

Boxes stay in a special room for 24 hours.

Each box is dropped 10 times on different sides and corners.

After each drop, they check for damage.

If the box passes, it is ready for real shipping.

Consistency

You want every box to look and work the same. Suppliers use many steps to keep quality steady, even for big orders:

They choose the right cardboard thickness for each box. This keeps boxes strong.

Digital printing keeps colors bright and matches your brand.

Features like dust flaps and self-locking tabs protect your products.

You can see a digital proof before they start making boxes. This helps you spot mistakes early.

Suppliers use recyclable materials to meet eco-friendly rules.

Some give you sample kits so you can check quality first.

Note: Good, steady quality means fewer returns and happy customers. Always check samples and proofs before a big order.

5. Sustainability

Certifications

You want to be sure your packaging is good for the planet. Mailer box suppliers use certifications to show they care. The Forest Stewardship Council (FSC) certification is the most famous label for paper and packaging. FSC has tough rules for forests and follows materials from trees to boxes. You see the FSC logo on lots of boxes. More than half of people around the world know this logo. Most people pick FSC-certified products because they trust it.

Suppliers also use the Recycled Claim Standard (RCS) for poly mailers and recycled stuff. RCS checks if recycled materials are real and follows them through the supply chain. If you see RCS100, the mailer uses only recycled resin. NexTrex® certification is another choice for thin film packaging. It shows the packaging can be recycled into composite lumber.

You can check a supplier’s certifications by looking for third-party logos and public reports. Suppliers who share their certification status and test results are open and honest. You can ask for details about recycled content, recyclability, and how to throw it away. This helps you avoid fake green claims and trust your supplier.

Tip: Always look for FSC, RCS, or NexTrex® logos on packaging. These labels mean the supplier meets high sustainability standards.

How suppliers verify certifications:

Look for third-party logos from groups like FSC or Textile Exchange.

Check reports and test results on the supplier’s website.

Ask for details about recycled content and disposal.

Confirm traceability with certification numbers.

Compare options using public certification data.

Eco-Friendly Practices

You want packaging that keeps your products safe and helps the earth. Top mailer box suppliers use many eco-friendly practices to help you meet your sustainability goals.

Suppliers use only recycled materials for custom mailers, like Kraft, Poly, Bubble, and Padded options.

Printing on recycled mailers lets you show off your brand and care for the planet.

You can order just one box, which cuts waste and gives you choices.

Custom sizes and all-over printing keep packaging green and nice-looking.

White-glove service mixes sustainability with a personal touch.

Online ordering makes picking green options easy.

Euro Tote-style bags use recycled materials for style and sustainability.

Shipping boxes use biodegradable and recyclable materials.

Water-activated paper tape replaces plastic tape for sealing.

Custom tissue paper and wrapping paper are eco-friendly instead of bubble wrap.

Suppliers remove plastic and non-paper parts to make recycling simple.

You can reuse kraft boxes for crafts, pet beds, or DIY projects.

Many brands lead in eco-friendly packaging. ASOS uses boxes with up to 90% recycled content and has a packaging return program. Calvin Klein and Gucci use less plastic and more recycled materials. Puma makes new packaging to cut waste.

Note: Picking suppliers with strong eco-friendly practices helps you protect the planet and build trust with your customers.

6. Mailer Box Supplier Selection

Picking the right mailer box supplier is important for your business. You want a partner who gives good quality and meets deadlines. The supplier should also help your brand look good. Here are some things to think about when you choose a supplier.

Reputation

A good reputation means you can trust the supplier. You should read reviews and talk to other customers. Look for suppliers with lots of good comments about their boxes and service. If a supplier has a good name, they usually deliver on time and fix problems fast.

Tip: Talk to other business owners about their supplier. Their advice can help you make a better choice.

You can also see if the supplier has won awards or has special certificates. These things show the supplier cares about doing a good job and making customers happy.

Experience

Experience is important when picking a mailer box supplier. Suppliers who have worked for many years know how to handle different jobs. They know what works best for many products and businesses. You should ask how long the supplier has made mailer boxes. Find out if they have helped businesses like yours before.

Here are some questions you can ask:

How long have you been in business?

Can you show examples of work like mine?

How do you handle custom orders?

A supplier with lots of experience can help you pick the right materials and box styles. They can also help you save money and make green choices.

Capacity

You need a supplier who can fill your order and do it on time. Capacity means the supplier has enough boxes, workers, and machines to finish your order fast. If your business grows, the supplier should be able to make more boxes for you.

Think about these things when you check capacity:

Does the supplier have enough materials ready?

Can they send boxes on time, even when busy?

Do they have many box styles and printing choices?

Will they give you a sample before making all the boxes?

A good supplier will show you how they make boxes and handle big orders. You want a partner who can grow with your business and keep things running well.

Note: Always ask for a sample before a big order. This lets you check the quality and avoid problems.

When you look at reputation, experience, and capacity, you help your business do well. The right mailer box supplier will help your brand, protect your products, and keep your customers happy.

7. Turnaround

Lead Times

You want your mailer boxes to arrive on time. Lead time means how long it takes to get your boxes after you order. Most suppliers need 10 to 30 business days to make custom packaging. The time depends on how many boxes you order and what kind you want. If you order just a few simple boxes, you might get them faster. If you want lots of boxes or special printing, it can take longer.

Suppliers get busy during holidays and big sales. Your order may take more time then. Always ask your supplier when your boxes will arrive before you order. This helps you plan your shipping and keeps your customers happy.

Tip: Order early if you need boxes for busy times like Black Friday or the holidays.

Here is a quick look at what changes lead times:

Processing

You want to know how suppliers handle your order and keep things moving. Suppliers use smart ways to make production and shipping faster, especially when they are busy.

Suppliers set up their warehouses to pick and pack quickly.

Machines scan, label, and ship boxes fast.

Extra workers help out during busy seasons.

Digital tools track inventory and shipping routes.

Some suppliers use third-party partners to handle more orders.

They guess when busy times will happen and get ready early.

Suppliers tell you if there are any changes or delays.

These steps help your orders arrive on time. Suppliers use technology like warehouse management systems and data tools. These help find problems early and keep things running well.

Note: Talking with your supplier helps you avoid surprises. Always ask how they handle orders when things get busy.

You can help by giving clear order details and planning ahead. When you know about lead times and processing, you can make better choices for your business. This keeps your products moving and your customers happy.

8. Pricing

Material Costs

Material costs are the biggest part of mailer box prices. The type and quality of materials you pick can change the price a lot. Thicker cardboard costs more than thin cardboard. If you want recycled or eco-friendly materials, you might pay more. These materials cost extra because more people want them and there are strict rules. The price of raw materials can go up or down. This depends on how much is available and what is happening in the world. Energy costs and recycling systems also make prices higher. Special textures or finishes will add to your cost. If you do not say exactly what materials you want, the price might change later.

Note: Picking sustainable or fancy materials shows you care about quality and the planet, but you may pay more for these choices.

Volume Discounts

You can save money if you order more boxes at once. Most mailer box suppliers give volume discounts. When you buy more, each box costs less. Here is a simple table that shows how prices change when you order more:

Suppliers like Cactus Containers and Packaging Supply Depot want you to ask about discounts for big or custom orders. You can get better deals if you plan ahead and buy in bulk.

Tip: If you know you will need more boxes later, order a bigger batch to get the best price per box.

Custom Charges

Custom features make your mailer boxes special, but they cost extra. You might pay more for:

Special printing, like full-color designs or foil stamping

Unique shapes, sizes, or die-cut windows

Custom inserts or dividers to protect your products

Premium finishes, such as matte, gloss, or spot UV

Rush orders or fast shipping

Each custom choice needs more work and materials. Suppliers usually give you a quote based on what you want. Always ask for a detailed price list before you order.

Remember: Custom boxes help your brand look professional, but plan your budget to cover these extra costs.

9. Design Support

In-House Teams

You get a big advantage when your mailer box supplier has an in-house design team. These teams work closely with you to turn your brand ideas into real packaging. You share your vision, and the team listens to your needs. They help you pick the right materials, colors, and finishes that match your brand. For example, Ashtonne Packaging’s design team guides clients from the first sketch to the final box. They make sure your packaging stands out in stores and online.

In-house teams use advanced digital printing, like CMYK with UV cure technology. This gives your boxes bright, long-lasting colors that match your brand. You can use easy online design tools and templates to create your own look. If you want to see your design before a big order, you can order a single custom-printed proof box. This lets you check the colors and design. The team also helps you choose strong materials, such as white corrugated cardboard, to keep your products safe and make your colors pop.

Clients often say these teams turn ideas into samples quickly. You get expert advice on what works best for your products. The result is packaging that looks great and helps people remember your brand. Good design support can even lead to more repeat customers.

Tip: Use your supplier’s design team to make your packaging unique and boost your brand’s image.

Collaboration

You play a key role in the design process. Suppliers want your input at every step. The collaboration starts with a simple questionnaire. You share your brand style, goals, and what you want your packaging to say. The supplier reviews your answers and asks questions to make sure they understand your needs.

Here is how the process usually works:

Fill out a design questionnaire about your brand and packaging needs.

Talk with the supplier to answer questions and finalize details.

Review the first box layout or digital proof sent by the supplier.

Get 3D renderings or a physical sample, depending on your order.

Give feedback and ask for changes if needed.

The supplier updates the design until you are happy.

Approve the final proof or sample before production starts.

You also get a consultation to discuss your brand’s story and target audience. The supplier creates prototypes using your favorite styles and materials. You give feedback, and the team makes changes until the design feels right. This back-and-forth ensures your packaging matches your brand and meets your needs.

Note: Stay involved in the design process. Your feedback helps create packaging that truly represents your brand and delights your customers.

10. Shipping

Packaging

You want your products to get to customers safely. Mailer box suppliers use smart ways to protect each item. They pick a box that fits your product just right. This keeps things from moving around and breaking. Suppliers use strong materials like single-wall or double-wall corrugated cardboard. These materials help the box stay strong and safe.

Suppliers often add extra protection inside the box. Bubble wrap, foam inserts, and air pillows help cushion your products. These things soak up bumps and stop items from shifting. Some suppliers use custom inserts or molded pulp trays. These fit your product’s shape and add more safety. Tamper-evident seals show if someone opened the box before you got it. Moisture-resistant materials keep out water and mold.

Here is a quick look at common packaging methods:

Tip: Ask your supplier how they pack your products. This helps you make sure your items stay safe and your customers are happy.

Delivery

You want your boxes to show up on time and in good shape. Mailer box suppliers work with trusted shipping companies. They track every order from the factory to your door. Most suppliers let you pick how fast you want your boxes. You can choose standard, express, or overnight shipping.

Suppliers pack boxes tightly to save space and lower shipping costs. They put clear labels on each package. This helps delivery drivers know how to handle your boxes. Some suppliers give you tracking numbers so you can watch your shipment online. If something goes wrong, you get updates quickly.

You can ask for special delivery choices. Some suppliers offer scheduled or weekend deliveries. This lets you pick when your products arrive.

Note: Always check delivery times before you order. Planning ahead helps you avoid late shipments, especially during busy times.

International

Sometimes you need to send products to other countries. Many mailer box suppliers can ship worldwide. They know the rules for customs and taxes in different places. Suppliers use strong packaging to keep your products safe on long trips.

You get help with paperwork and customs forms. Suppliers often use big carriers like FedEx, UPS, or DHL. These companies offer tracking and fast shipping to other countries. Some suppliers have eco-friendly shipping for international orders.

Here are some things to think about for international shipping:

Check if your supplier helps with customs paperwork.

Ask about extra fees or taxes for your country.

Make sure your packaging follows international rules.

Use tracking to watch your shipment as it travels.

Tip: Pick a supplier who knows about international shipping. This helps you avoid problems and keeps your customers happy, no matter where they live.

You have learned the key facts about how mailer box suppliers work. When picking a supplier, remember these tips: Look at the price and see if you get discounts for big orders. Check if you can get your money back if there is a problem. Make sure customer service is helpful and design support is easy to use. Find out how long it takes to make and ship your boxes. Ask for samples so you can check if the quality is good. See if you can change the box style to match your brand. Learn about the smallest order you can make and what products you can pick. Try out design tools and ask if they offer eco-friendly choices. These steps help you pick a supplier who fits your needs and helps your business grow.

FAQ

What materials do mailer box suppliers use most often?

Suppliers mostly use corrugated cardboard, chipboard, and kraft paper. These materials keep products safe and are good for printing. Many suppliers also have recycled and eco-friendly choices.

How do you check if a supplier uses sustainable practices?

Look for certifications like FSC or RCS on their products. Ask the supplier to show proof of these certifications. You can also check their website for reports about being green. Suppliers who care about the earth will share this information with you.

Can you order custom sizes and designs for mailer boxes?

Yes, you can pick the size, shape, and design you want. Suppliers have online tools and samples to help you choose. You can add your logo, colors, and special features to match your brand.

How long does it take to get your mailer boxes?

It usually takes 10 to 30 business days to get your boxes. The time depends on how many you order and if you want special features. Always ask your supplier for a delivery date before you order.

What is the minimum order quantity for mailer boxes?

Some suppliers let you buy just one box. Others want you to order at least 10 or even 100 boxes. Always check with your supplier before you order.

Do suppliers offer discounts for large orders?

You pay less per box when you buy more at once. Many suppliers give discounts for big orders. Ask for a price list or a quote if you want to order a lot.

How do suppliers make sure your boxes arrive safely?

Suppliers use strong materials and add inserts or padding inside. They test the packaging by dropping it to see if it holds up. You get a tracking number to watch your shipment.

Can you get help with designing your mailer box?

You can work with the supplier’s design team. They help you pick materials, colors, and layouts. You get to see proofs and samples before they make all your boxes.