What choices do you have for mailer box customization? You need to ask your mailer box supplier clear questions. This helps you not make mistakes. It also keeps your packaging plan safe. When you look at things like production and lead times, you find problems early. You can stop delays before they happen. If you use digital tools instead of email, talking is easier. You also make fewer mistakes. Use the questions below as your checklist when you work with any mailer box supplier.

Tip: Talking early and often with your mailer box supplier means you get fewer surprises and better results.

Key Takeaways

Pick the best material for your mailer box. Think about your product’s weight and size. Also, think about how far it will travel. This keeps your items safe. It also helps show off your brand.

Choose printing methods that fit your design needs. Pick finishes that match your budget. This makes your packaging look special. It also helps protect your products.

Ask your supplier about the minimum order quantity. This helps you avoid surprises. Look for flexible options for small or big orders.

Learn about all the costs. This includes materials, printing, setup, and shipping. Planning your budget is important. You can save money with simple designs. You can also save by ordering in bulk.

Ask how long production and delivery will take. This helps you plan your orders. It also helps you avoid delays. Ask about rush options if you need boxes quickly.

Pick eco-friendly materials and inks. Make sure they have certifications. This shows customers you care about the environment. It also helps lower your carbon footprint.

Ask for samples and prototypes. Test your box’s size and strength. Check how it looks before making a big order. This helps you avoid costly mistakes.

Work with suppliers who have lots of experience. Choose ones who make boxes themselves. Good support is important. They can help you create a great unboxing experience. This helps build your brand.

1.Material Options

When you want to make mailer boxes, start with the material. The right material keeps your items safe. It also helps your brand look special. Here are some things to ask your supplier about material choices.

Durability

Your mailer boxes need to keep your products safe. They should protect them from when you send them until they arrive. Most suppliers have white cardboard with a matte finish. Some have kraft cardboard for a natural look. Others offer Dreamcoat™ with a satin finish. For strong boxes, you might see E-flute (1/16") or B-flute (1/8") corrugated cardboard. E-flute is good for light things. B-flute is better for heavy things up to 30 pounds.

If you ship breakable or heavy things, you may need thicker boxes or more padding. Mailer boxes made from light corrugated cardboard are good for branding. They also give a nice unboxing experience. But they can get crushed if handled roughly or shipped far. For local orders or things that are not breakable, mailer boxes work well and look nice.

Tip: Pick a box that matches your product’s weight and how far it will travel. If you do not know what to pick, ask your supplier for help.

Suitability

Picking the right material means thinking about your product. Think about its size, shape, and weight. Here is a checklist to help you:

Look at your product. Is it heavy, breakable, or shaped in a strange way?

Think about how far it will go. Will it be tossed around or get hot or cold?

Make a budget that fits your product’s price.

Think about your brand’s style. Do you want a kraft look or a bright white box?

See what other brands use. Do you want to be different or the same?

Talk to your supplier early. They can help you choose the best material and save money.

Eco-Friendly Choices

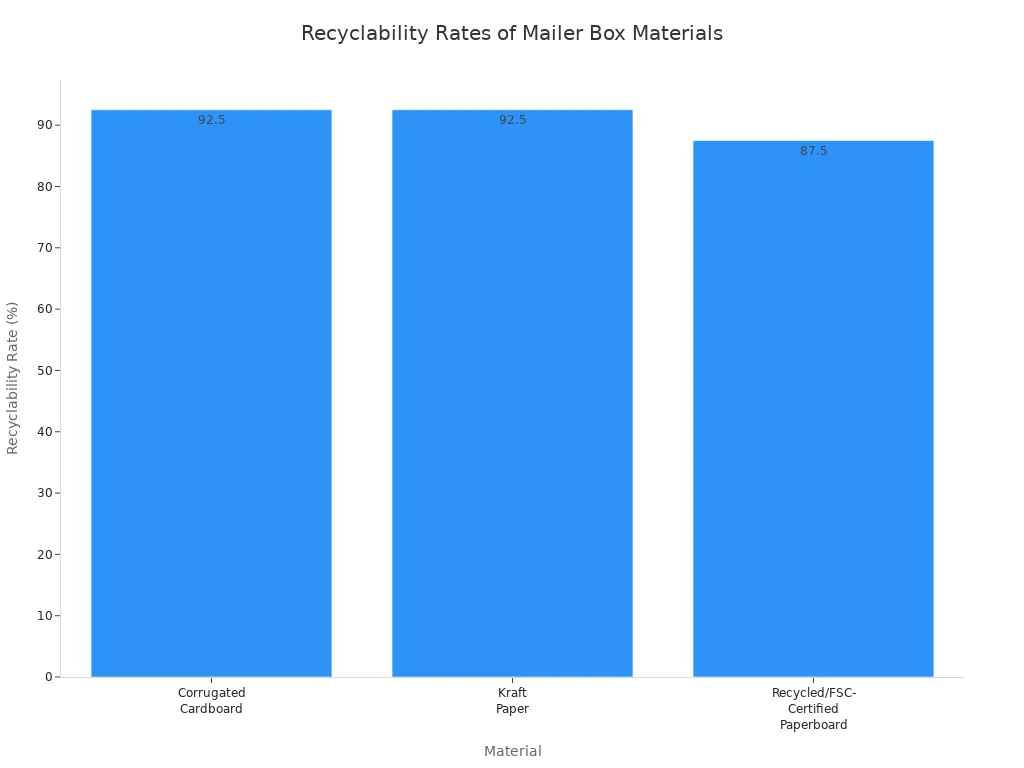

Many people care about the environment. You might want to pick eco-friendly materials. Most suppliers have boxes that can be recycled or composted. Corrugated cardboard and kraft paper are easy to recycle. They have high recycling rates.

Here is a table to show how common materials compare:

Suppliers often recycle almost all of their box scraps. The corrugated cardboard industry recycles most fibers. They use a lot of recycled stuff and try to use less energy. When you pick eco-friendly materials, you show customers you care about the earth.

Note: Ask your supplier if their materials are FSC-certified or made from recycled stuff. This can help your brand look good and make customers happy.

2. Design and Branding

Your mailer box is more than just a container. It tells your brand story. You want your packaging to stand out and make a great first impression. Let’s look at the main ways you can customize your mailer box design.

Printing Methods

You have several printing choices for your mailer boxes. Each method gives you different results and fits different needs.

Digital Printing: This method works well for small orders and complex designs. You can print many colors in one pass. You don’t need plates, so you save money and time. Digital printing lets you change your design quickly. If you run a startup or want to test new ideas, this is a smart choice. You get sharp, photo-quality images, and you can switch designs even in the middle of an order.

Flexographic Printing: This method suits big orders with simple designs. It uses special plates for each color. Flexographic printing works well on rough surfaces and can print up to 10 colors in one pass. If you want fast production for large batches, this is a good option.

Lithographic Printing: Some suppliers offer this for very high-quality images. It’s best for luxury packaging but costs more.

Tip: Ask your supplier which printing method fits your order size and design needs. You can save money and get the look you want.

Coating and Finish

The coating and finish you choose can change how your box looks and feels. It also protects your product during shipping.

High Gloss: This finish makes your box shiny and bright. It grabs attention and makes colors pop.

Soft Matte: You get a smooth, non-reflective surface. It feels nice to touch and gives a modern look.

Spot UV: This adds shiny, raised areas to highlight logos or patterns. It makes your design look fancy.

Foil Stamping: You can add gold or silver details. This makes your box look luxurious.

Custom Inserts & Dividers: These keep your products safe inside the box.

Here’s a quick table to help you compare:

Note: The right finish can boost your brand image and keep your products safe. Ask your supplier for samples to see and feel the options.

Size Adjustments

You want your mailer box to fit your product perfectly. Suppliers offer both standard sizes and custom dimensions. You can pick the length, width, and depth that match your needs. Custom sizing helps you avoid wasted space and keeps your items secure.

You can personalize both the inside and outside of your box.

Choose from styles like Regular Slotted Carton or Full Overlap Carton.

Select finishes such as matte white, kraft, or premium gloss.

Some suppliers offer eco-friendly inks, like 100% water-based options.

If you ask for a special size, your supplier will tell you if it’s possible. Sometimes machines can’t make every size, but you’ll know before you order.

Tip: Custom sizes help your products arrive safely and make your brand look professional. Always check with your supplier about size limits and pricing.

3. Minimum Order Quantity

When you start planning your mailer box order, you need to know about minimum order quantity, or MOQ. This number tells you the smallest amount of boxes you can buy from a supplier. If you ignore MOQ, you might spend too much or end up with more boxes than you need. You want to match your order size to your budget and your sales plan.

Standard MOQ

Most suppliers set a standard MOQ for custom mailer boxes. This helps them manage production costs and keep prices fair. Some suppliers let you order just one box, while others ask for a dozen or more. You should always check the MOQ before you start designing your packaging.

Here’s a quick table to show you how different suppliers handle MOQ:

You see, some suppliers are very flexible. You can order just one box if you want to test your design. Others need you to buy at least 12 boxes. If you plan a big launch, you might want to order more. If you run a small shop or just want samples, look for suppliers with low or no MOQ.

Tip: Always ask your supplier about their MOQ before you start your order. This helps you avoid surprises and keeps your costs under control.

Flexibility

You might worry that MOQ will stop you from trying new packaging ideas. Good news—many suppliers now offer flexible options for small businesses and startups. In the past, you had to order hundreds of boxes because suppliers used old printing methods. Now, digital printing lets you order as few as 25 or 50 boxes. You can test new designs, run seasonal promotions, or change your packaging without spending a lot.

Suppliers know that small businesses need to stay agile. They use smart inventory tracking and digital printing to lower MOQs. Some even let you negotiate the minimum if you build a strong relationship. If you care about the environment, you’ll like that lower MOQs help reduce waste. Local suppliers often offer smaller minimums to attract new brands.

You can use these flexible options to:

Try out new packaging designs without risk.

Order just what you need for a special event or holiday.

Save money by matching your order size to your sales.

If you want to keep your business nimble, ask your supplier about their MOQ policy. You might find that you can order fewer boxes and still get great quality. Technology makes it easier for you to get what you need, when you need it.

Note: If you’re a small business or startup, don’t be afraid to ask for a lower MOQ. Suppliers want to work with you and help you grow.

4. Pricing and Fees

When you order custom mailer boxes, you want to know exactly what you’re paying for. Pricing can look confusing at first, but if you break it down, you’ll see where your money goes. Let’s look at the main things that affect the price of your boxes.

Cost Breakdown

You don’t want surprises on your bill. Always ask your supplier for a full cost breakdown. Here’s what usually makes up the price:

Materials: The type and weight of the cardboard or board matter. E-flute and B-flute cost different amounts. Lighter boards usually cost less.

Printing and Decoration: Digital CMYK printing is common and lets you use lots of colors without extra fees. If you want foil stamping or embossing, expect to pay more.

Box Structure: Simple shapes cost less. If you want a fancy box with special folds or inserts, the price goes up.

Minimum Order Quantities: Some suppliers charge more if you order just a few boxes.

Tooling and Setup: Custom dies and machine setup can add to your bill, especially for new designs.

Shipping Costs: The size and weight of your boxes affect shipping. Custom sizes can help you save here.

Proofing and Samples: If you want a printed sample or proof before your full order, there may be a small fee.

Tip: You can save money by choosing simple designs, lighter materials, and standard sizes. Ask your supplier for ways to cut costs without losing quality.

Here’s a quick table to help you see what might show up on your invoice:

Volume Discounts

Ordering more boxes can save you a lot of money. Most suppliers offer volume discounts. The price per box drops as your order gets bigger. For example, if you order 5,000 boxes or more, you may get a much lower price per unit. Some companies even offer prices 45%–60% lower than others when you buy in bulk.

You don’t have to run a huge business to get a deal. Even small increases in your order size can help you save. Always ask your supplier about bulk pricing. Sometimes, just adding a few more boxes to your order can make a big difference.

Note: If you plan to grow your business, think about ordering more boxes at once. You’ll save money in the long run.

Payment Terms

You should always know when and how to pay for your boxes. Suppliers have different payment terms. Some want full payment upfront, while others let you pay half now and half when your boxes ship. A few may offer payment plans for big orders.

Ask about:

Accepted payment methods (credit card, bank transfer, PayPal)

Deposit requirements

Payment deadlines

Refund or cancellation policies

If you’re a new customer, you might need to pay in advance. Once you build trust, your supplier may offer better terms.

Tip: Clear payment terms help you plan your budget and avoid delays. Always get payment details in writing before you place your order.

5. Lead Time

When you buy custom mailer boxes, you want to know when they will get to you. Lead time means how long it takes from when you order until you get your boxes. If you plan early, you will not run out of boxes or miss a big sale. Here is what you should ask your supplier about lead time.

Production Time

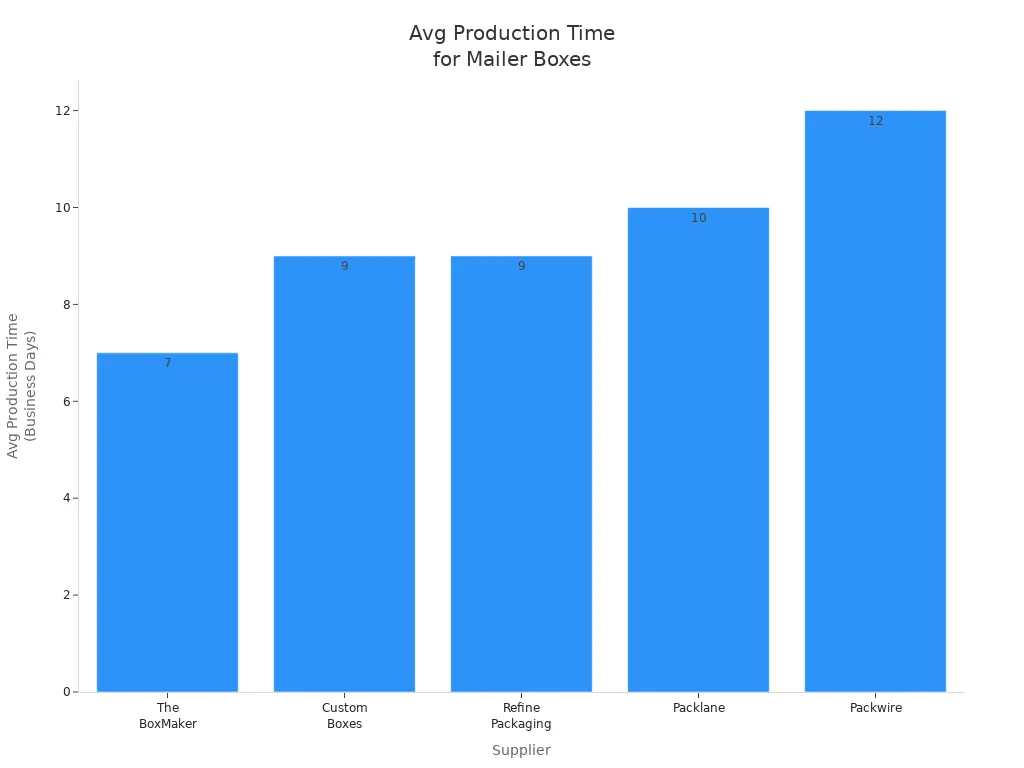

Production time is how long it takes to make your boxes after you say the design is good. Every supplier has a different speed. Some are faster than others. Look at this table to compare:

Most suppliers start making your boxes after you say the artwork is okay. If you wait to approve, your order will take longer. Some suppliers count shipping in their time, but others do not. Always ask your supplier when they start counting days.

Tip: Approve your design fast to get your boxes sooner. Ask if the timeline includes shipping.

Delivery Estimates

You want to know when your boxes will arrive at your place. Delivery estimates help you plan your stock and shipping. Here are some things to remember:

Most suppliers say standard delivery takes about 3-4 business days.

You might get next-day delivery if you order early.

Busy times or holidays can make lead times longer.

Customer service gives the best delivery date after you confirm your order.

Most orders take 8-10 business days after you approve your design.

Big or special boxes may take more time to make and ship.

Delivery times are just guesses. Weather or holidays can change them.

Note: Always ask your supplier for the newest delivery estimate. If you have a deadline, tell them as soon as you can.

Rush Orders

Sometimes you need your boxes very fast. Maybe you have a last-minute event or a big order. Many suppliers can rush your order if you need it. Here is what you can do:

Ask about faster shipping if you need your boxes soon.

Some companies can make and ship boxes in one or two days for an extra fee.

You can ask for a price quote if you need your boxes super fast.

Suppliers like Packola and NextDayFlyers have “Get it FAST!” options for urgent orders.

If you need your boxes quickly, talk to your supplier before you order. They will tell you what they can do and how much it costs.

Tip: Rush orders cost more, but they help if you are in a hurry. Always ask about rush options if you need your boxes fast.

If you ask about production time, delivery, and rush orders, you can plan better and avoid problems. Your supplier wants to help you meet your deadlines, so keep talking to them!

6. Sustainability

You want your mailer boxes to look nice and help the earth. Many brands pick eco-friendly packaging because customers care about nature. Here are the main things to ask your supplier about sustainability.

Recycled Materials

Choosing recycled materials for your mailer boxes helps the planet. Most suppliers have boxes made from recycled cardboard or paperboard. These materials use less energy and water than new ones. You help keep trash out of landfills and show customers you care.

Look for boxes with post-consumer recycled content.

Ask if the cardboard is FSC-certified or from good sources.

Some suppliers use recycled fibers for both boxes and inserts.

If you want to be even greener, ask about biodegradable or compostable boxes. These break down faster and make less waste. You can also ask if your supplier recycles scraps from making boxes.

Tip: Using recycled materials lowers your carbon footprint and makes your brand look eco-friendly.

Certifications

Certifications prove your packaging is really sustainable. You do not want to fall for fake green claims, so check for third-party labels. These certifications show your supplier meets strict rules for the environment.

Here’s a table of common certifications you might see:

You can ask your supplier which certifications they have. These labels help you build trust with customers and show you care about the earth.

Note: Certifications like FSC and Cradle to Cradle help you avoid fake green claims and prove your boxes are really sustainable.

Printing Inks

Ink matters for sustainability too. Some inks can hurt the earth or make recycling harder. You want to pick inks that are safe and green.

Algae Ink™ is the world’s most sustainable ink. It uses pigment from algae cells and is water-based. This ink captures more carbon than it uses, so it is carbon-negative.

Water-based and soy-based inks are also good choices. They use fewer chemicals and are better for recycling.

Using too much ink can make boxes harder to recycle. Try to keep your design simple for easier recycling.

Some suppliers, like EcoEnclose, offer custom printing with black algae ink on recycled mailers. This lets you show off your brand and help the planet at the same time.

Tip: Ask your supplier about their ink choices. Picking sustainable inks helps your boxes look good and stay eco-friendly. 🌱

7. Samples and Prototyping

Before you buy a lot of mailer boxes, you should see what you are getting. Samples and prototypes let you check your packaging first. You can touch and test the box before you spend money. This step helps you avoid surprises. It also makes you feel sure about your choice.

Sample Types

There are different sample options from your mailer box supplier. Each one helps you in a special way. Here is a table to show the choices:

You can order a pre-printed sample kit to see the box in person. This helps you check the material and print quality. Suppliers use corrugated cardboard, kraft stock, or rigid cardstock for prototypes. You can pick finishes like soft velvet touch, matte, or gloss. Some suppliers give free design help, digital proofs, or video mockups for hard designs.

Tip: Ask for a sample that looks like your final box. This helps you find problems early.

Costs

Sample costs are usually low so you can test first. For example, BoxUp sells plain samples for $1 plus shipping. If you want a custom-printed proof, you pay for one box and shipping. Packlane lets you order single proof boxes with no setup fees.

Sometimes you pay a sample fee at the start. Many suppliers give this money back if you order a lot of boxes. This means you can check your box and not lose money if you buy more later.

Note: Ask your supplier if they remove sample fees for big orders. This saves you money as your business grows.

Testing

Testing your sample is important before you order many boxes. Here is how it works:

You talk to your supplier and say yes to the design.

The supplier makes different sample types:

Structural samples check the box’s size and strength.

Simplified samples show basic printing and material.

Pre-production samples match the final box with finishes and textures.

You check the sample for fit, strength, and looks.

Suppliers use good materials and printing to protect your product.

Quality teams watch every step to keep standards high.

You say yes to the prototype before the supplier makes your full order.

This process helps you avoid mistakes that cost money. You feel sure your packaging will work well.

🛠️ Pro Tip: Test your sample with your real product inside. This way, you know your box will protect your product and look good for your customers.

8. Mailer Box Supplier Experience

Manufacturer vs. Distributor

You should know if your mailer box supplier makes the boxes or just sells them. Manufacturers make the boxes in their own factories. This means you get more choices for size and design. You can ask for special features and get answers fast. Prices are lower because there is no middleman. Distributors buy boxes from other companies and sell them to you. They do not make the boxes themselves. You might pay more because they add extra fees. You may not get as many custom options. It can take longer to get your boxes because they depend on other companies.

Manufacturers let you pick more designs and sizes.

Distributors have fewer choices and cost more.

Manufacturers can change orders and delivery times faster.

Tip: Ask your supplier if they make the boxes or just sell them. This helps you plan your money and get what you want.

Track Record

Pick a mailer box supplier with a good history. Good suppliers send boxes on time and keep them strong. This keeps your business safe and your brand looking good. Strong packaging stops damage and keeps customers happy. Fast delivery means you do not miss sales or run out of boxes.

Here are signs your supplier is reliable:

They always have enough boxes, even when it is busy.

They deliver when they say they will. You can check reviews.

Their boxes use strong materials that meet rules.

Top suppliers use new machines and check quality often. They have good shipping systems. When you trust your supplier, you feel sure about your boxes. Your brand looks better and customers stay loyal.

Support Services

A good mailer box supplier does more than just sell boxes. They help you with design, testing, and shipping. Some give you online tools to plan your orders. You can get advice on how your packaging should look. They help you test boxes to make sure they are strong. You can save money with tips on packing and shipping.

Here’s what you might get:

Help with design and artwork.

Tests to check box strength and safety.

Checks to make sure boxes follow rules.

Training for your team about packaging.

Online tools to track and plan orders.

Quality checks to keep standards high.

Shipping help to save money.

Help with sending orders for online stores.

Advice on using eco-friendly materials.

Some suppliers help you follow safety laws. They give you papers and instructions to pass checks. They also test your boxes to make sure they are safe.

Structural Features and Unboxing Experience

Strong boxes keep your products safe. Corrugated cardboard helps protect against bumps. Self-locking boxes stay closed without tape. Custom sizes stop things from moving and breaking. You can add inserts or padding for more safety. Pick the right flute type, like E-flute or B-flute, for extra strength.

Corrugated cardboard makes boxes tough.

Self-locking boxes stay shut.

Inserts keep breakable things safe.

Different box styles, like Roll End Tuck Top, close neatly.

Unboxing is important too. A nice box makes customers feel special. Bright colors and fun shapes make people happy. Personal notes add a nice touch. Customers share unboxing online, which helps your brand. Good packaging makes your product look fancy and keeps buyers coming back.

Note: Most buyers judge your brand by the box. Make your mailer box supplier part of your brand’s story.

When you talk to your mailer box supplier, knowing what to ask helps you avoid problems. Use these eight questions to guide you:

Make sure you know about printing, colors, finishes, and where your logo goes.

Find out the smallest number of boxes you can order and how long it takes to make them.

Ask for samples so you can check if the box fits and is good quality.

Talk clearly with your supplier so you can trust them and fix issues quickly.

Good packaging begins when you ask smart questions and talk honestly.

FAQ

What is the best material for custom mailer boxes?

You should pick corrugated cardboard for most products. It’s strong and protects your items. If you want an eco-friendly option, choose kraft paper. Ask your supplier for advice based on your product’s weight and shipping needs.

Can I order just a few custom mailer boxes?

Yes, many suppliers let you order small amounts. Some even offer single box samples. This helps you test your design before you buy more. Always check the minimum order quantity with your supplier.

How long does it take to get my custom boxes?

Most suppliers need 7–14 business days to make your boxes after you approve the design. Shipping takes a few more days. If you need them faster, ask about rush options. Plan ahead to avoid delays.

Are custom mailer boxes recyclable?

Almost all custom mailer boxes are recyclable. Corrugated cardboard and kraft paper break down easily. If you use special coatings or lots of ink, recycling may be harder. Ask your supplier about the best eco-friendly choices.

Can I see a sample before placing a big order?

You can always ask for a sample. Suppliers offer plain, printed, or digital samples. This lets you check the size, design, and quality. Some suppliers refund the sample cost if you place a large order.

What printing options do I have for my design?

You can choose digital, flexographic, or lithographic printing. Digital works best for small orders and colorful designs. Flexographic is good for big orders with simple graphics. Ask your supplier which method fits your needs.

How do I make my mailer box stand out?

Try bold colors, unique finishes, or custom inserts. Add your logo and a fun message inside the box. A great unboxing experience makes customers remember your brand. Ask your supplier for creative ideas!

Do I need special packaging for fragile items?

Yes, you should use thicker cardboard and add inserts or padding. This keeps your products safe during shipping. Tell your supplier if your items are breakable. They can suggest the best options for protection.