Luxury paper box makers are changing packaging with eco-friendly methods, particularly in the realm of custom paper boxes wholesale. They focus on carbon-neutral work by using green materials and clean energy. This change matches the rising need for biodegradable packaging.

The demand for fancy biodegradable packaging, including custom paper boxes wholesale, is growing fast.

Spending on green solutions is helping this growth.

Experts say the world’s biodegradable packaging market will hit $166.2 billion by 2032.

These actions lower harm to nature and make custom paper boxes wholesale more attractive.

Key Takeaways

Fancy paper box makers are using earth-friendly methods to help nature.

Making products this way helps the planet and makes customers happy.

New tools and smart ideas cut waste and save energy, helping factories stay green.

The Role of Sustainability in Luxury Manufacturing

Consumer Demand for Sustainable Luxury Packaging

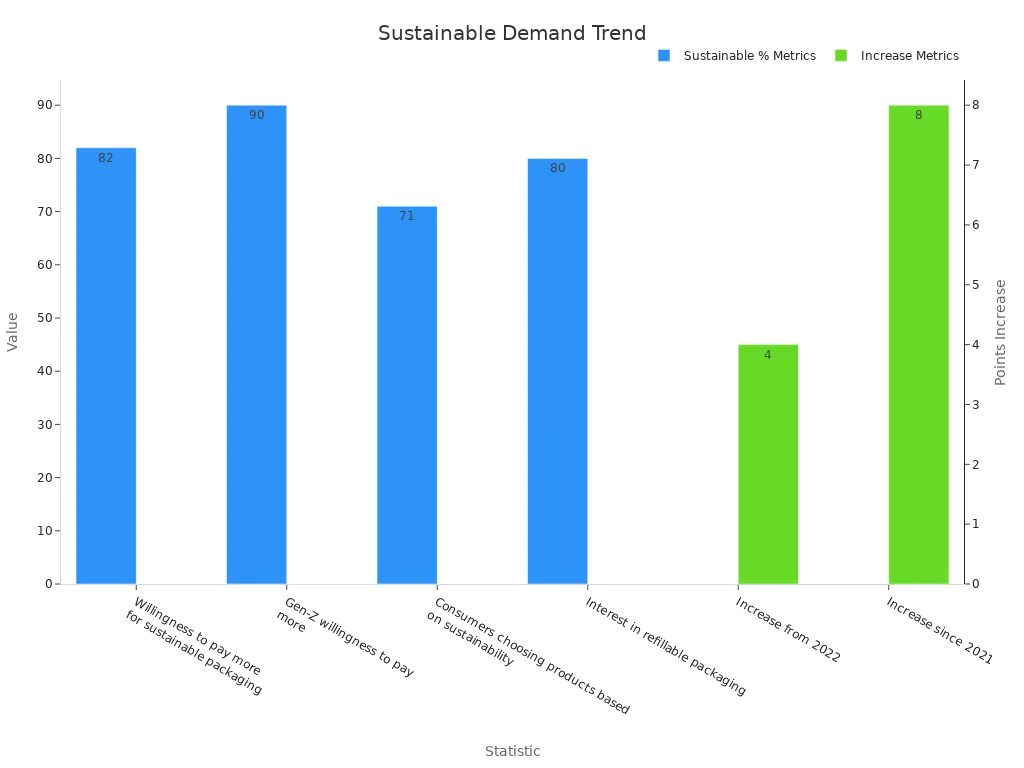

Sustainability is now a big deal for shoppers, especially in luxury. Many people prefer products that match their eco-friendly values. This has pushed luxury brands to use greener packaging. For example, 71% of shoppers pick items based on eco-friendliness. Also, 82% are okay paying more for green packaging, with 90% of Gen-Z leading this trend.

Luxury paper box makers now create smart, eco-friendly designs. These designs cut down harm to nature and meet the need for responsible packaging.

Environmental Benefits of Sustainable Paper Manufacturing

Making paper sustainably helps the environment in big ways. In the U.S., the paper industry stops 181 million metric tons of CO2 yearly by using biomass energy. This is like taking 35 million cars off the road. Also, managing forests well absorbs more CO2 than it gives off, cutting over 13% of U.S. yearly emissions.

By using less water, fewer fossil fuels, and avoiding clear-cutting, the industry lowers its impact. These steps show how luxury packaging can help fight climate change while staying high-quality.

Competitive Edge Through Sustainability

Being sustainable gives brands a big advantage. Companies using green methods can enter new markets and connect better with customers. For instance, Trimo, a top sandwich panel maker, uses Environmental Product Declarations (EPDs) to stay ahead.

Luxury paper box makers can also gain by showing they care about the planet. These actions boost their image and help them grow by solving eco and social problems.

Strategies for Carbon-Neutral Factory Operations

Using Sustainable Materials and Improving Supply Chains

Using eco-friendly materials helps factories lower carbon emissions. About 80% of big companies' emissions come from their supply chains. Better supply chain methods can cut these emissions a lot. For example, FSC-certified paper is eco-friendly and high-quality. Unbleached kraft paper is strong and good for the planet. It’s a favorite for custom paper boxes wholesale.

Making packaging with less material also helps the environment. Working with green suppliers lowers harm to nature. Checking materials often leads to new ideas and better business. Companies like Apple show that green supply chains save money and energy. This proves being eco-friendly is smart and profitable.

Saving Energy and Using Renewable Power

Saving energy and using clean power are key for green factories. Factories can use tech to track and predict emissions. Watching renewable energy use gives accurate data on pollution. Quick reports on green goals help improve factory work.

Some companies show how these ideas work. Columbia Manufacturing saves 147,000 gallons of water daily. They also cut harmful waste by 98%. Polartec lowered its carbon footprint by 21%. Stainless Steel Coatings reduced waste costs by 52%. These examples show how clean energy and saving power improve factories.

Cutting Waste and Recycling for Custom Paper Boxes Wholesale

Managing waste is important for eco-friendly factories. Recycling paper and cardboard cuts waste for custom paper boxes wholesale. Factories can reuse materials with closed-loop systems. This reduces trash sent to landfills.

Sustainable forestry keeps raw materials available and protects nature. By recycling and cutting waste, luxury paper box makers can go green. These actions meet customer needs for eco-friendly products. They also help the planet and make brands look better.

Innovations in Sustainable Paper Manufacturing

Better Machines for Cleaner Production

Cleaner production starts with better machines. Factories now use energy-saving tools to make more while using less power. For example, 3D printing creates items as needed, cutting waste and saving energy. It also skips the need for extra tools. These new methods help factories pollute less and work smarter.

New machines also use clean energy and eco-friendly materials. They are designed to harm the planet less. This way, factories can make products while still protecting nature. It’s good for both businesses and the Earth.

Safer Glues and Non-Toxic Materials

Glues and materials are key to green manufacturing. A new glue made from lignin, a pulp byproduct, is changing things.This lignin glue replaces harmful formaldehyde glues. It lowers pollution and is safer for workers and users. It shows that being green can also mean being safe.

Using non-toxic materials helps the planet and makes luxury paper boxes better.

Smart Tools for Saving Resources

Smart tools are changing how factories save resources. Sensors now track energy use and pollution levels. Connected devices and smart systems make machines work better.

AI tools study energy use and suggest ways to save power.

One tissue company used AI to cut chemical use by 25%.

These tools also lower pollution, helping factories meet green goals.

By using these smart tools, factories save resources and go green. This helps them build a cleaner future.

Circular Economy and Lifecycle Analysis in Packaging

Making Recyclable and Reusable Packaging

Creating packaging for a circular economy starts with smart materials. Strong and eco-friendly options like glass or metal work well. These materials can be reused many times. For example, the Clever Little Bag cuts cardboard use by 65% and includes a reusable bag. Flat-pack trays use less material but stay sturdy. These ideas show how small changes help the planet.

Reusable designs and return systems are also important. They keep packaging in use longer and reduce trash. By focusing on recyclable and reusable packaging, we can protect nature and support a circular economy.

Studying Packaging Lifecycles for Sustainability

To see how packaging affects the planet, we use lifecycle studies. These studies check every step, from making materials to throwing them away. They show where we can improve eco-friendliness. For example, using recycled materials lowers waste and carbon emissions.

Different tools may give different results, but the goal is clear. We want to design better products that harm the planet less. Lifecycle studies help us make smart choices for long-term sustainability.

Teamwork for Circular Supply Chains

Teamwork is key to building a circular economy. Companies like L'Oréal work with schools and groups to improve packaging. Kering teams up with NGOs to reuse leather and fabric scraps. These partnerships show how working together helps sustainability.

Ivalua says suppliers, factories, stores, and shoppers must all work together. By teaming up, we can use more recycled materials and cut carbon footprints. These efforts push us toward a circular economy and set an example for others to follow.

Luxury paper box makers are changing how factories stay green. They use clean energy and eco-friendly methods to lead the way. Their work inspires others to follow and make better choices. These actions show that being green and fancy can go together.

FAQ

What is a carbon-neutral factory?

A carbon-neutral factory makes up for the carbon it releases. It does this by cutting emissions and using green methods like solar power or planting trees.

How do luxury paper box makers cut carbon emissions?

They use clean energy and better supply chains. They also pick eco-friendly materials to lower their carbon impact while keeping quality high.

Why does carbon neutrality matter in factories?

Carbon neutrality fights climate change and protects the environment. It also meets customer demand for eco-friendly products, especially in luxury packaging.