Key Takeaways

Pulp prices can change by 20-30% each year, affecting costs.

Using many suppliers and managing stock well can prevent shortages.

Using technology to plan ahead makes work easier and faster.

Pulp Price Volatility and Its Impact on Paper Box Manufacture

Key Drivers of Pulp Price Fluctuations

Pulp prices often fluctuate due to several factors. Market dynamics, such as supply chain disruptions and demand surges, play a significant role. For instance, when demand for paper products rises sharply, pulp prices tend to increase. Similarly, supply chain issues, like transportation delays or raw material shortages, can limit availability and drive up costs.

Research also highlights the relationship between international pulp prices and producer inventories. A long-term equilibrium exists between pulp prices and NORSCAN inventory levels, which means that changes in inventory can directly influence pricing trends. This connection underscores the importance of monitoring inventory levels to predict price movements.

Geopolitical events and economic pressures further complicate the situation. Trade restrictions, tariffs, or currency fluctuations can impact the cost of importing or exporting pulp. These factors create a volatile environment, making it challenging for manufacturers to plan their budgets effectively.

Consequences for Paper Box Manufacturers

Pulp price volatility directly affects the profitability of paper box manufacture. Raw material costs form a significant portion of the total production cost. When pulp prices rise, manufacturers face higher costs of goods sold (COGS). This increase forces them to either absorb the costs, reducing profit margins, or raise product prices, which may affect competitiveness.

Profitability depends heavily on managing these raw material costs. Companies that fail to adapt risk financial losses. Investors also monitor these costs closely, as they influence earnings and overall business performance. For manufacturers, staying ahead of these fluctuations is crucial to maintaining stability and growth in a competitive market.

Managing Supply Chain Risks in Paper Box Manufacture

Addressing Transportation and Logistics Challenges

Transportation and logistics challenges often disrupt the supply chain. I have observed that economic headwinds, global conflicts, and labour shortages frequently impact logistics performance. These factors create bottlenecks, delay shipments, and increase costs. To address these issues, companies rely on logistics performance indicators. These indicators help monitor efficiency and identify problems early. For example, tracking delivery times and order accuracy allows businesses to optimise routes and improve operational efficiency.

Key performance indicators (KPIs) also play a vital role in managing risks. They provide real-time insights into transportation risks and help identify the lowest-risk alternatives. By using data-driven decision-making, companies can adapt to disruptions and maintain focus on their goals. This approach ensures that logistics operations remain resilient, even during challenging times.

Mitigating Raw Material Shortages

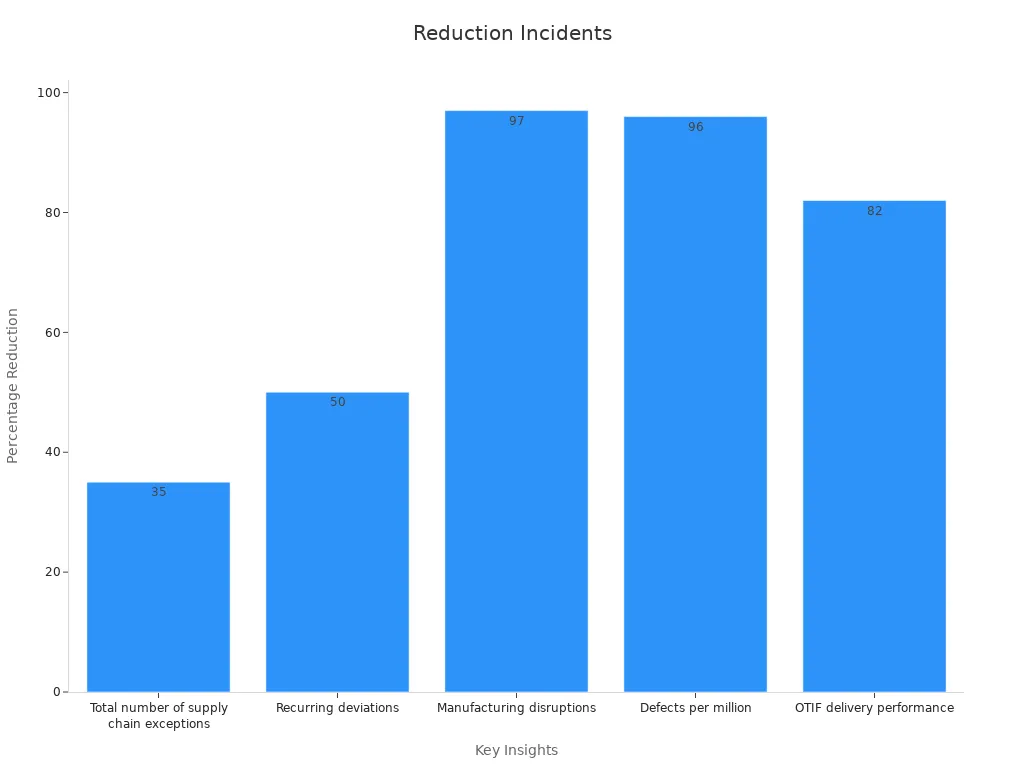

Raw material shortages pose a significant risk to paper box manufacture. I have seen how supply chain exceptions and recurring deviations disrupt production. However, implementing strategic measures can reduce these incidents. For instance, optimising inventory management and diversifying suppliers can minimise shortages. A recent study showed that such strategies reduced manufacturing disruptions by up to 97% and improved on-time delivery performance by 82%.

These improvements highlight the importance of proactive planning. By addressing shortages early, manufacturers can ensure a steady supply of raw materials and maintain production continuity.

Adapting to Geopolitical and Economic Pressures

Geopolitical tensions and economic pressures significantly affect supply chain stability. Trade between geopolitically aligned countries has increased by 6% since 2018, while trade between rivals has decreased by 4%. I have noticed that firms are adjusting their supply chains to mitigate risks. Many reduce their supply bases in high-risk regions, which increases complexity but ensures stability.

State relations also influence global supply chains. Political risks often lead to disruptions, forcing companies to reconfigure their operations. By diversifying supply bases and building resilience, manufacturers can adapt to these pressures. This strategy ensures that paper box manufacture remains stable, even in uncertain times.

Strategic Solutions for Raw Material Challenges

Supplier Diversification and Network Resilience

I have seen how supplier diversification strengthens supply chains. By working with multiple suppliers, manufacturers reduce their dependence on a single source. This approach ensures a steady flow of raw materials, even during disruptions. Building network resilience also plays a critical role. For instance, companies that use high-quality master data are better equipped to handle supply chain challenges.

According to a 2022 McKinsey & Company survey, supply chain leaders with high-quality master data were 1.5 times more likely to report no challenges from the 2021 supply chain impacts.

Effective risk management fosters resilience. Businesses that plan and prepare can thrive, even in unpredictable times. I always recommend investing in robust supplier relationships and leveraging data to anticipate risks.

Technology Adoption for Forecasting and Planning

Technology adoption transforms raw material planning. Digital forecasting tools improve accuracy and efficiency. For example, a juice manufacturer using supply chain forecasting tools achieved a 20% increase in forecasting accuracy and reduced overtime hours from 25% to 8%.

AI systems also optimise inventory management by analysing historical data and real-time market signals. During peak seasons, AI adjusts demand forecasts by up to 20%, ensuring timely raw material orders. These advancements help paper box manufacture maintain stability and meet customer demands.

Sustainable Practices and Innovative Materials

Sustainability reduces raw material volatility. I have observed how practices like recycling and resource optimisation minimise reliance on new materials. Engaging in circular economy initiatives also helps reuse materials, reducing the need for fresh resources.

Innovative materials also contribute to cost savings and environmental benefits. Materials informatics, for example, optimises processes and reduces waste. Predictive maintenance models extend equipment lifespan, cutting costs and fostering transparency. These practices not only enhance sustainability but also build trust with stakeholders.

Pulp price volatility and supply chain risks challenge paper box manufacturers daily. I believe adopting strategic solutions is essential for overcoming these hurdles. Supplier diversification reduces reliance on single sources and improves resilience.

Onboarding new suppliers helps navigate tariff volatility.

PO automation provides real-time alerts, enabling swift procurement adjustments.

Regular audits identify inefficiencies, ensuring operational continuity.

Technology adoption and sustainable practices also play a vital role. AI-powered platforms enhance transparency, while recycling minimises raw material dependency. By embracing these strategies, manufacturers can safeguard operations and thrive in a competitive market.

FAQ

What are the main factors causing pulp price volatility?

Pulp prices fluctuate due to demand surges, supply chain disruptions, geopolitical tensions, and currency changes. Monitoring these factors helps manufacturers anticipate and manage price changes effectively.

How can manufacturers reduce supply chain risks?

I recommend diversifying suppliers, adopting forecasting technologies, and building resilient networks. These strategies minimise disruptions and ensure a steady flow of raw materials.

Why is sustainability important in paper box manufacturing?

Sustainability reduces dependency on new materials, lowers costs, and builds trust with stakeholders. Recycling and innovative materials also contribute to environmental benefits and operational efficiency.