Making good manufacturing paper boxes requires careful work at every step. From sourcing materials to constructing the final box, each part is crucial. For instance, about 92% of cardboard is recycled worldwide, demonstrating how much the manufacturing paper boxes industry cares about the environment. Innovative ideas help enhance this process, ensuring it remains efficient and high-quality.

Key Takeaways

Making paper boxes from recycled items saves trees and energy. It is a better choice for the environment.

Machines and smart tools make production faster and more exact. This helps lower waste and costs.

Testing often makes sure recycled boxes are strong, long-lasting, and look nice.

Importance of Recycled Content in Manufacturing Paper Boxes

Environmental and Sustainability Benefits

Using recycled materials to make paper boxes helps the environment. About half of recycled paper is used for cardboard boxes. This reduces the need for new materials, saving trees and energy. For example, corrugated cardboard has about 89% recycled content, showing its role in sustainability.

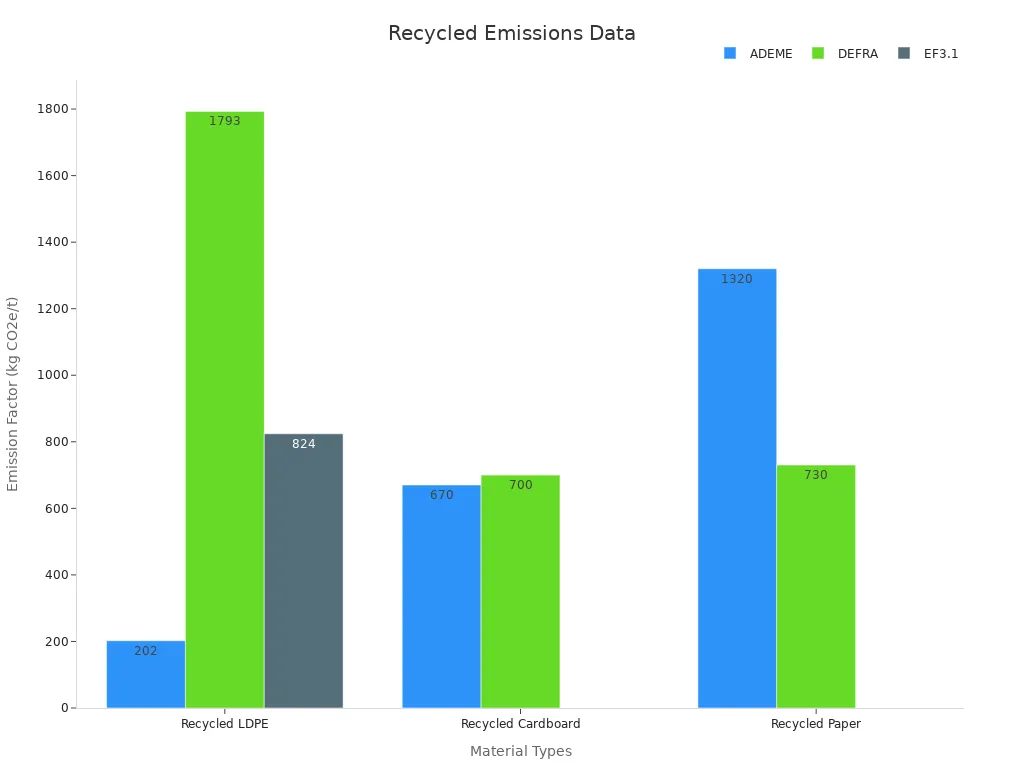

Recycling cuts waste and supports reusing materials. It keeps trash out of landfills and saves natural resources. Recycled cardboard has less environmental impact than new cardboard. Studies show recycled cardboard emits 670 kg CO2e per ton, while new cardboard emits 801 kg CO2e per ton.

Sustainability is more than reducing waste. It includes making products that can break down or be reused. By using eco-friendly materials, companies can meet green goals and make recyclable packaging.

Addressing Market Demand for Eco-Friendly Packaging

More people want eco-friendly packaging today. In 2024, recycled paper made up 55.7% of the market, showing people prefer sustainable options. This rise is due to better recycling and awareness of environmental issues.

The global paper packaging market was worth $416.5 billion in 2022. By 2028, it may grow to $503.1 billion. This shows how important sustainable packaging is to consumers. People now want recyclable and biodegradable packaging, pushing companies to create eco-friendly designs.

Eco-friendly packaging also helps reduce waste. Using recyclable materials lets companies make green packaging that appeals to eco-conscious buyers. These changes help protect the planet and meet the demand for recyclable paper packaging.

Innovations in Recycling Technology for Manufacturing Paper Boxes

Advanced Sorting and Cleaning Methods

Recycling begins with sorting and cleaning materials. New technology has improved this step a lot. Machines now use cameras and sensors to sort waste by type. These machines make sure only the right materials are recycled. Robots with AI also help by sorting faster and better than people. This saves money and makes the process quicker.

Some systems, like GAINnext, work super fast—up to 2,000 items per minute. That’s 33 times faster than humans! Sensors work together to make sorting more accurate. They ensure only clean materials are used for paper boxes. Deep learning tools also remove dirt from the paper. These technologies make recycling faster and create better recycled paper.

Enhanced Pulping and Fiber Treatment Techniques

After sorting, materials go to the pulping stage. Here, paper is broken into fibers. New pulping methods use less water and energy, making it eco-friendly. Closed-loop recycling is another cool idea. It recovers most fibers from old boxes, cutting waste.

Fiber treatment has also gotten better. New methods clean and strengthen fibers for strong paper boxes. Special tools find and remove dirt to make the paper look good. These improvements help meet the need for eco-friendly packaging.

Step-by-Step Manufacturing Process for Recycled Paper Boxes

Sourcing and Preparing Recycled Materials

The first step is finding recycled materials that are high-quality. Good materials are important for making strong boxes. To check the quality, advanced tools like X-ray fluorescence and moisture tests are used. These tools find dirt and measure water levels in the materials. This ensures the recycled materials work as well as new ones.

After testing, the materials are cleaned and sorted. Cleaning removes dirt, and sorting organizes them for the next step. This preparation improves the recycled paper boxes and speeds up the manufacturing process.

Pulping and Forming Paperboard

Next, the materials are turned into pulp. Water and machines break the materials into fibers. New pulping methods use less water and energy, making the process eco-friendly.

The fibers are treated to make them stronger and look better. This helps create durable and nice-looking paperboard. The fibers are then pressed and dried into sheets. These sheets are the base for making paper boxes.

Printing, Cutting, and Assembling Boxes

In the last step, the paperboard becomes packaging. Designs or logos are printed using inks that are safe for the environment. Machines cut the sheets into shapes and sizes needed for boxes.

Automation helps make the process faster and more accurate. It also reduces mistakes and waste. Systems watch the process to ensure quality. Finally, the pieces are folded and glued into sturdy boxes ready for packaging.

Pro Tip: Watching the process closely helps keep the boxes consistent and high-quality.

Ensuring Quality in Manufacturing Paper Boxes

Testing for Strength and Durability

Testing is key to making strong recycled paper boxes. These tests check if boxes can handle shipping, storage, and daily use. One test, the Bursting Strength Test, shows how much pressure a box can take before breaking. This helps decide how much weight the box can hold.

Another test, the Edge Crush Test, checks if the box can handle heavy stacking. The Box Compression Test measures how much weight a box can take before it bends. This is important for shipping large amounts. To check water resistance, glue lines are tested, and a Cobb Sizing Tester measures how much water the box absorbs. These tests ensure boxes stay strong, even in wet conditions.

Here’s a summary of the quality tests used:

These tests make sure the boxes are durable and reliable.

Achieving Consistent Appearance and Finish

Besides strength, the look of the boxes matters too. A neat appearance helps with branding and customer satisfaction. Advanced printing methods ensure colors and designs are clear and accurate. Visual checks confirm the boxes look as expected. Material checks ensure the paper meets quality standards.

Dimensional testing ensures boxes fit products perfectly. Machines measure sizes to avoid mistakes. Structural tests confirm the boxes are sturdy. Sustainability audits check if materials are recyclable and eco-friendly. These steps help create packaging that is both functional and attractive.

In short, careful testing and technology ensure the boxes are strong, good-looking, and eco-friendly. This process reduces waste and supports green packaging solutions.

Efficiency Improvements in Manufacturing Paper Boxes

Automation and Smart Technologies

Automation and smart tools have changed how paper boxes are made. These technologies make production faster and more accurate. They also help reduce waste. For example, automated systems watch the process in real time. They fix errors quickly and ensure each box meets high standards. This cuts down on waste and boosts efficiency.

Smart tools also improve design. They let companies create custom packaging quickly for different needs. This is important in today’s competitive market. Automation also helps with quality checks. Machines find defects right away, so fewer manual checks are needed. This ensures all boxes are recyclable and eco-friendly.

Here’s a table showing how automation and smart tools help:

These tools make manufacturing smarter and better for the planet.

Energy and Resource Optimization

Saving energy and resources is key to sustainable manufacturing. Using energy-saving machines can lower energy use by 30%. This saves money and reduces harm to the environment. Regular energy checks keep machines running efficiently, cutting costs even more.

Better material use also helps. High-quality parts make machines last longer, up to 40% more. This means fewer replacements and less waste. Recycling is also important. It reduces trash and makes sure materials are reused well.

Here’s a table showing how these strategies save money:

By focusing on energy and resources, we can make eco-friendly packaging that saves money and helps the planet.

Making strong recycled paper boxes needs good materials and careful work. New tools like automation and energy-saving machines make it better.

Caring for the planet is important. It saves resources and supports green goals. Using smart technology, we make sturdy, nice-looking boxes and cut waste. Let’s build a cleaner future together. 🌱

FAQ

Why are recycled paper boxes good for the environment?

Recycled paper boxes are made from reused materials. This helps cut down on waste and saves natural resources. They also use less water and energy to make, which makes them a greener choice. 🌱

How do I check the quality of recycled paper boxes?

You should test their strength, durability, and water resistance. Use modern tools to find any flaws and make sure they look and work well.

Are recycled paper boxes affordable?

Absolutely! Recycled boxes cost less because they need fewer raw materials and less energy. Smart machines and automation also help lower production costs while keeping the quality high.