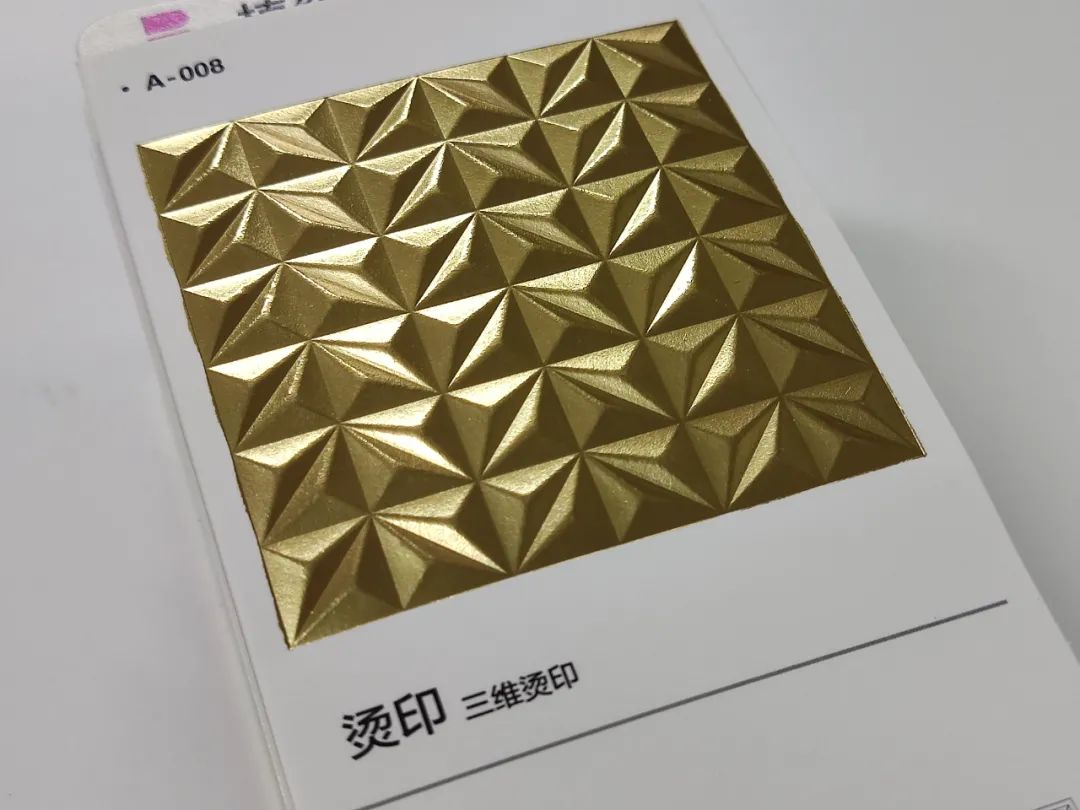

Special printing process Several types of special printing processes, fully know the type and actual effect of the process, and better apply the special printing process. Bronzing FOIL STAMPING Hot stamping is the process of hot stamping electrochemical aluminum foil on a substrate through a certain temperature and pressure, commonly known as “hot stamping” or “hot silver”.The metallic luster of hot stamping has a strong decorative effect and a strong visual impact.According to the different substrate materials, it can be divided into paper bronzing, fabric bronzing, leather bronzing and plastic bronzing.According to the different bronzing templates and processing techniques, there are hot stamping, cold stamping, single-layer bronzing, multiple bronzing and three-dimensional bronzing.

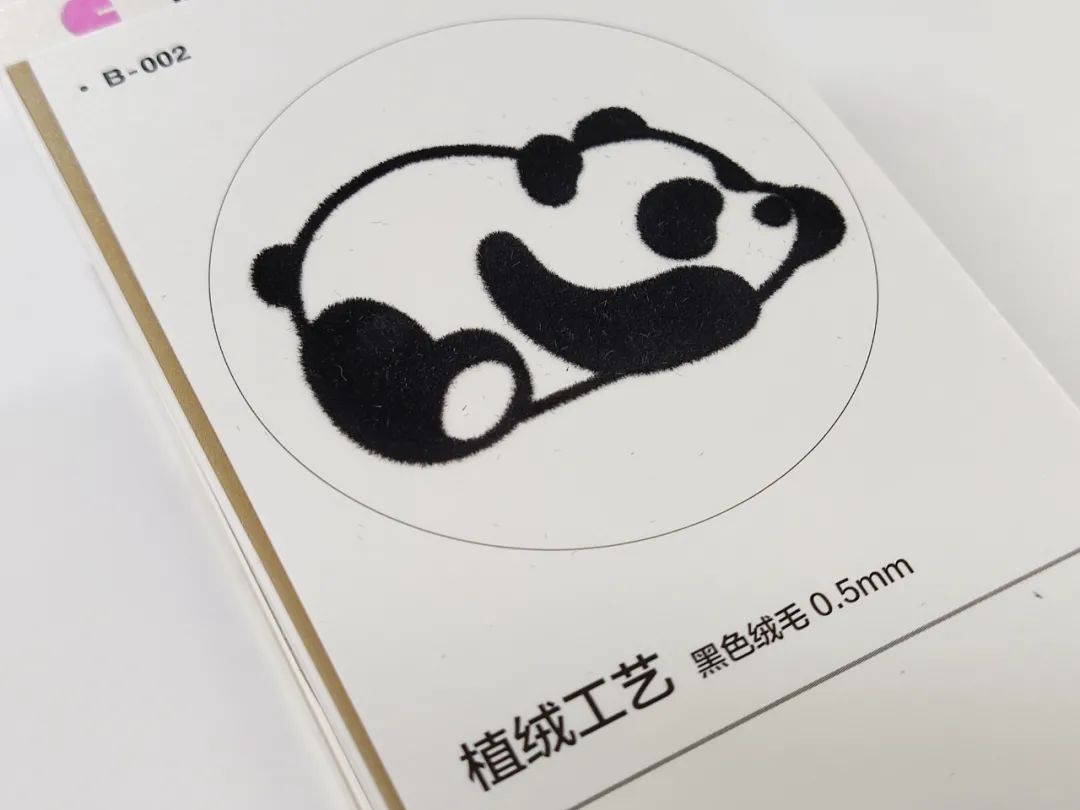

Flocking FOIL PROCESS Flocking is the transplanting of special fibers onto a substrate. The carriers available for flocking are paper, leather, ceramics, metals, plastics, etc., and the colors of the fibers for flocking are various colors except gold and silver.

Partial UVUV COATING Local UV is short for ”local UV glazing", which is the process of curing with ultraviolet light after printing local varnish to form a local brightening effect.This process makes the printed matter show high brightness, transparency and wear resistance locally.The surface of the printed matter that has been partially UV-treated has a more textured and three-dimensional sense, highlighting the visual effect of local bright light.

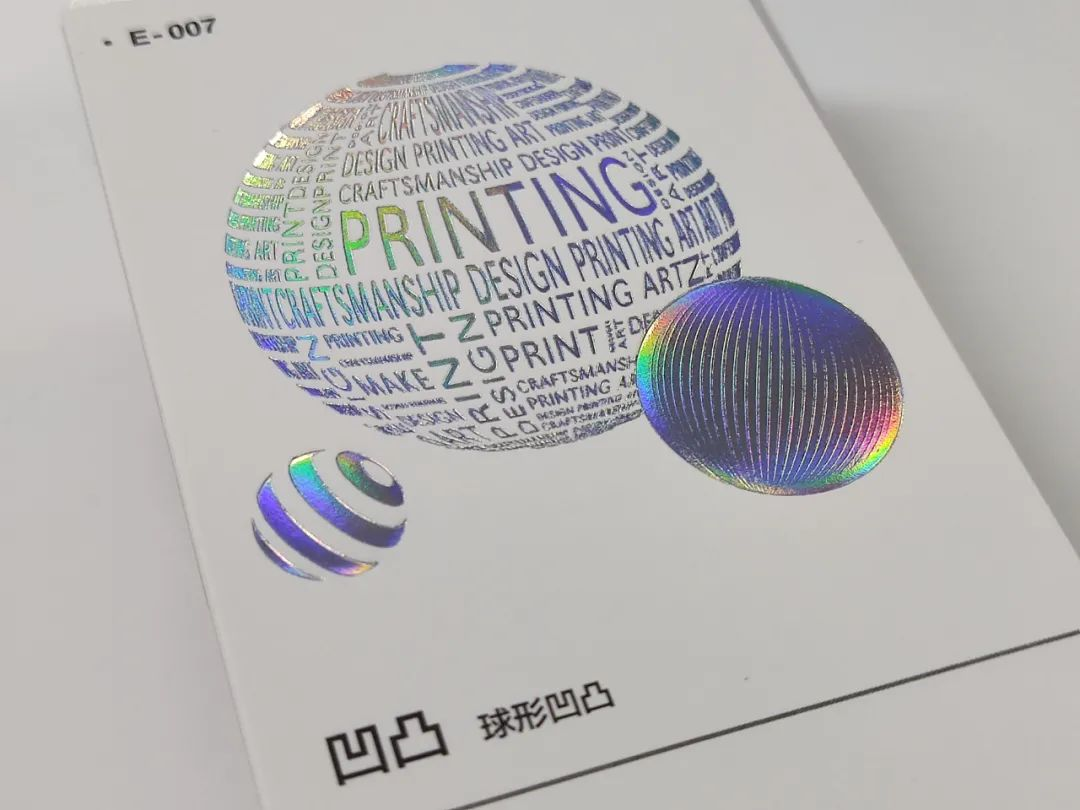

凹凸CONCAVE-CONVEX

Concave-convex is a special process technology in the finishing processing of printed matter surface. It is suitable for Yin (concave) and Yang (convex) molds, and mechanically exerts pressure that exceeds the elastic limit of the printed matter substrate to perform artistic processing on the surface of the printed matter.Among them, the process of applying pressure from the back of the paper to make the surface swell is commonly known as “embossing”; while the process of applying pressure from the front of the paper to make the surface concave is called “embossing”, which is a common technique in the post-processing process of the printed surface.

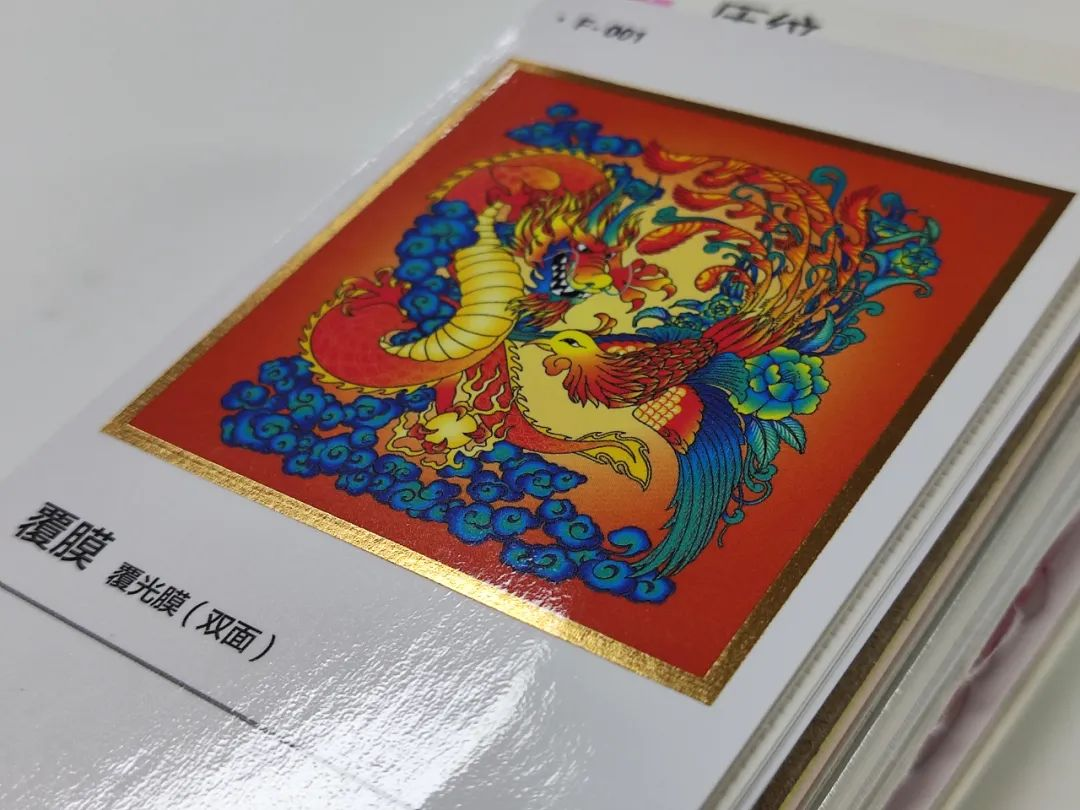

Film MULCHING Laminating, also known as gluing, is the process of heating, pressurizing, and cooling the plastic film coated with an adhesive and the paper-based printed matter to cover the surface of the printed matter with a layer of transparent plastic film, forming a paper-plastic integrated post-press processing technology.The laminating process is highly protective, protects the printing color from scratches and enhances the toughness of the printed product, and has a bright surface and strong performance, which is mostly used for product prints.

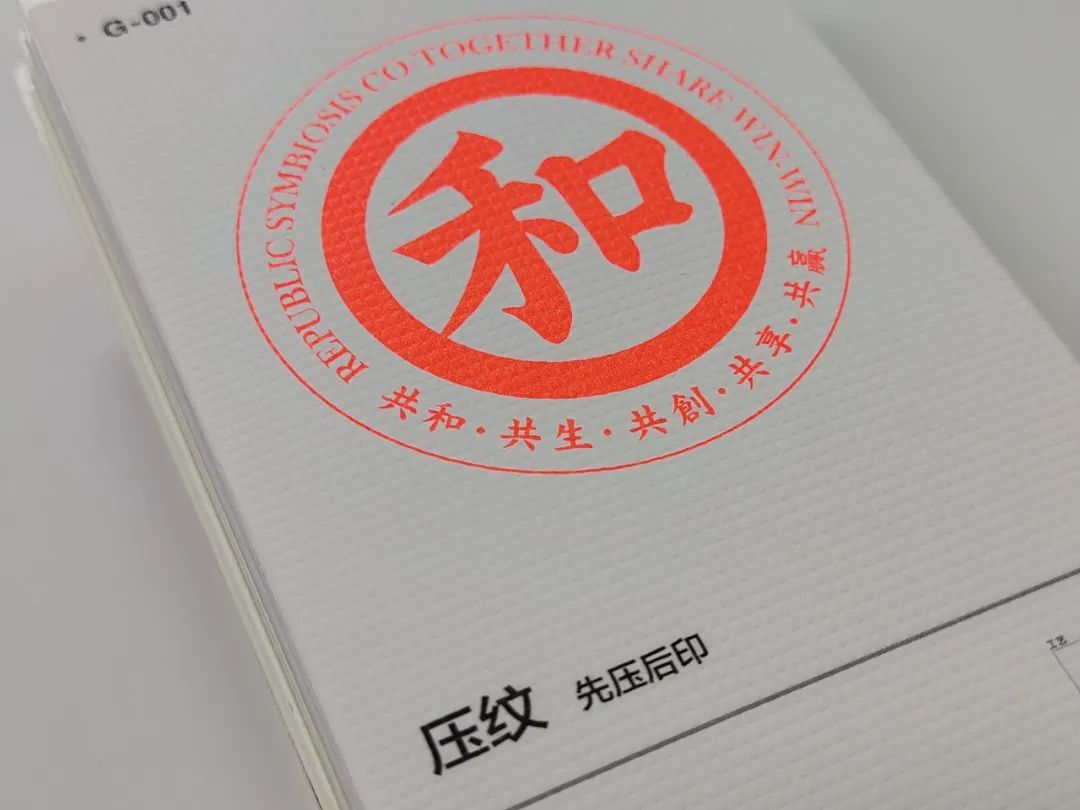

Embossing The embossing in the printing process is basically the application of an embossing machine to select and process on a specific texture roller, whichisenvironmentallyfriendly,convenient,fast and cost-effective.Embossing presents different patterns or textures of different shades on the surface of the material, which has a clear sense of texture, which makes the material significantly change into another kind of performance effect.Embossing is divided into full version embossing and partial embossing, or double-sided embossing and single-sided embossing.

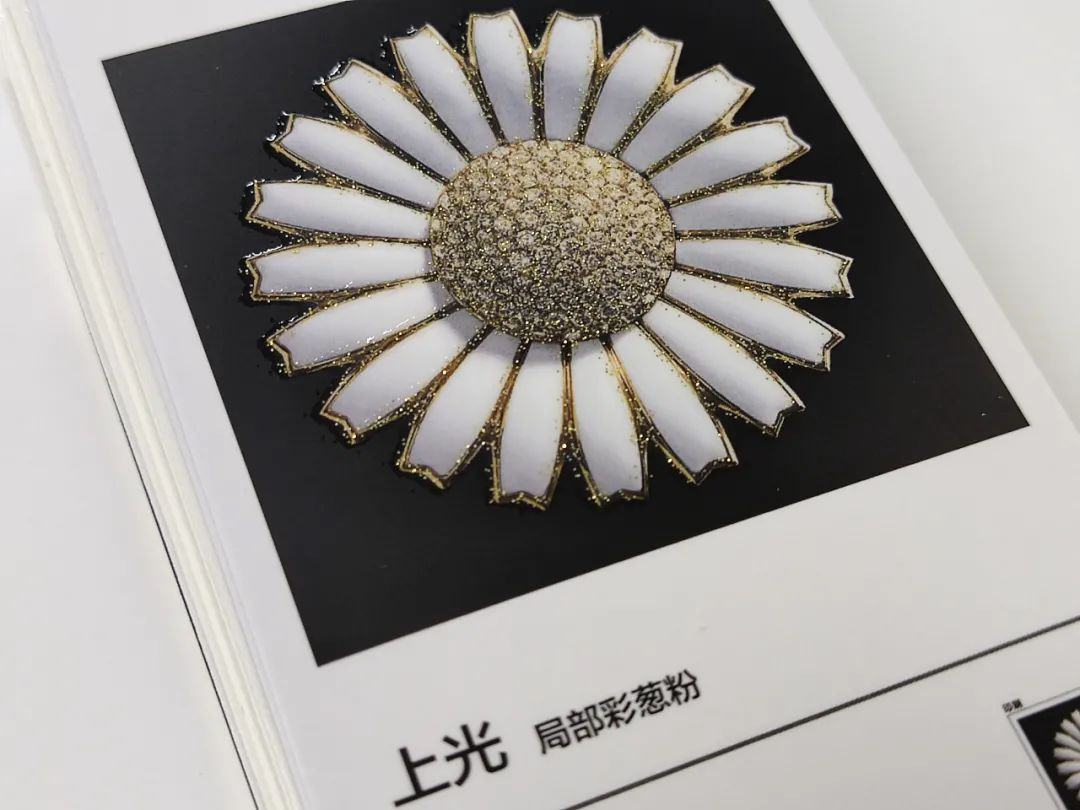

GLAZING PROCESS The most important purpose of glazing is to add value to the packaging print, because the surface of the polished print adds a bright luster and three-dimensional sense, and the appearance.The texture on it is more refined, and it is easier to become the visual focus in the dazzling display of goods.It can be used for various occasions, can retain the texture of the paper, can also be partially coated, highlighting the grade of the print, and is very widely used.

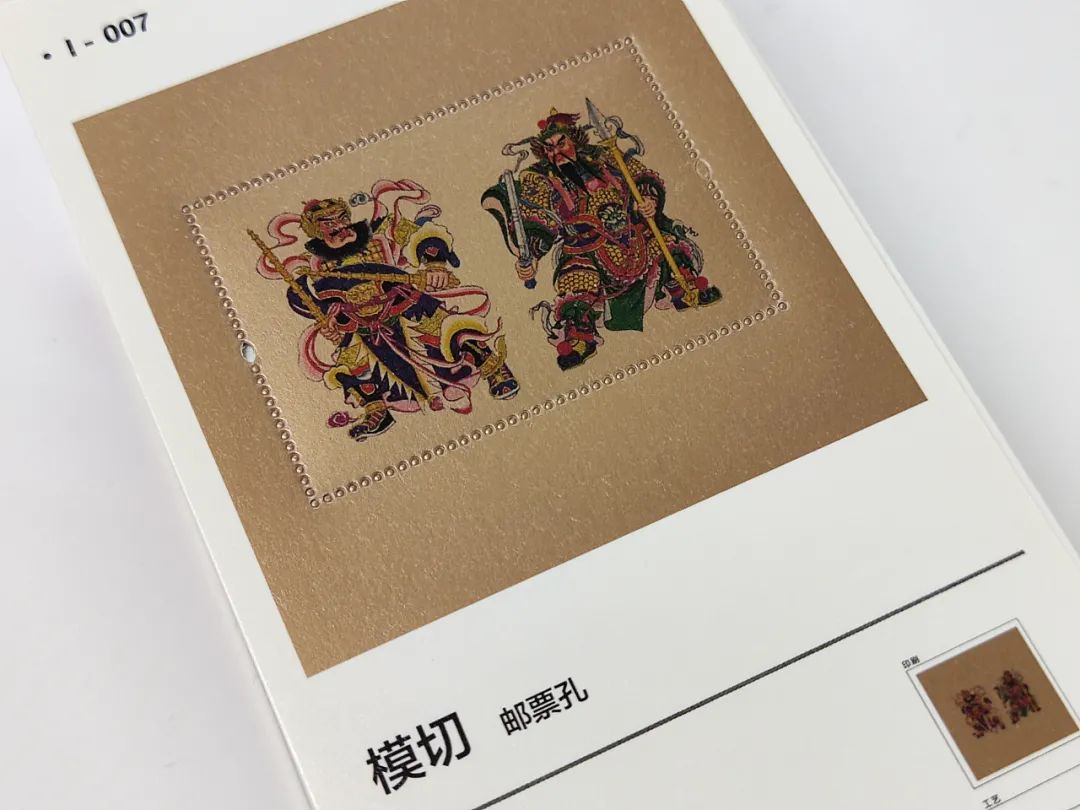

Die CUTTING TECHNOLOGY Usually, the die-cutting process is the process of combining the die-cutting knife and the crimping knife in the same template to process the shape of the material.In daily production, it is usually referred to as die-cutting or molding.It can be operated as a separate process or the two processes can be combined into one process on the same machine. The die-cutting version is equipped with both steel knives and steel wires, which do not conflict with each other.

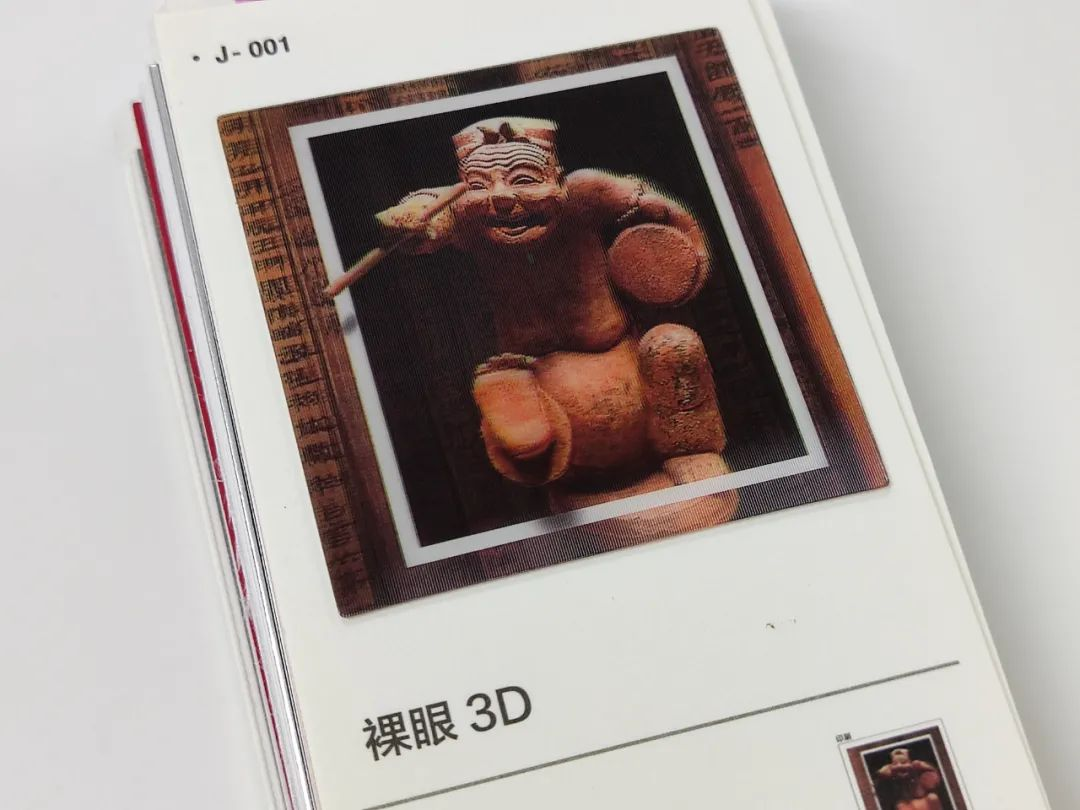

3D grating 3D GRATING TECHNOLOGY 3D grating process usually refers to three-dimensional grating printing.It uses a principle that simulates the spatial difference that can be generated by the spacing of the human eye, and records pixels of different angles and levels in the photosensitive material.Then, with the help of the composite of grating materials, the three-dimensional effect and even virtual reality are presented on the two-dimensional flat image.In this way, people can clearly and accurately feel the wonderful fun of three-dimensional pictures without the help of any tools and directly observing through their eyes.