You see corrugated shipping boxes almost everywhere. These boxes have three layers. Two flat linerboards are on the outside. A wavy fluted medium is in the middle. Manufacturers make them to keep your things safe when shipping or storing. People like these boxes more each year. They are strong, good for the environment, and save money.

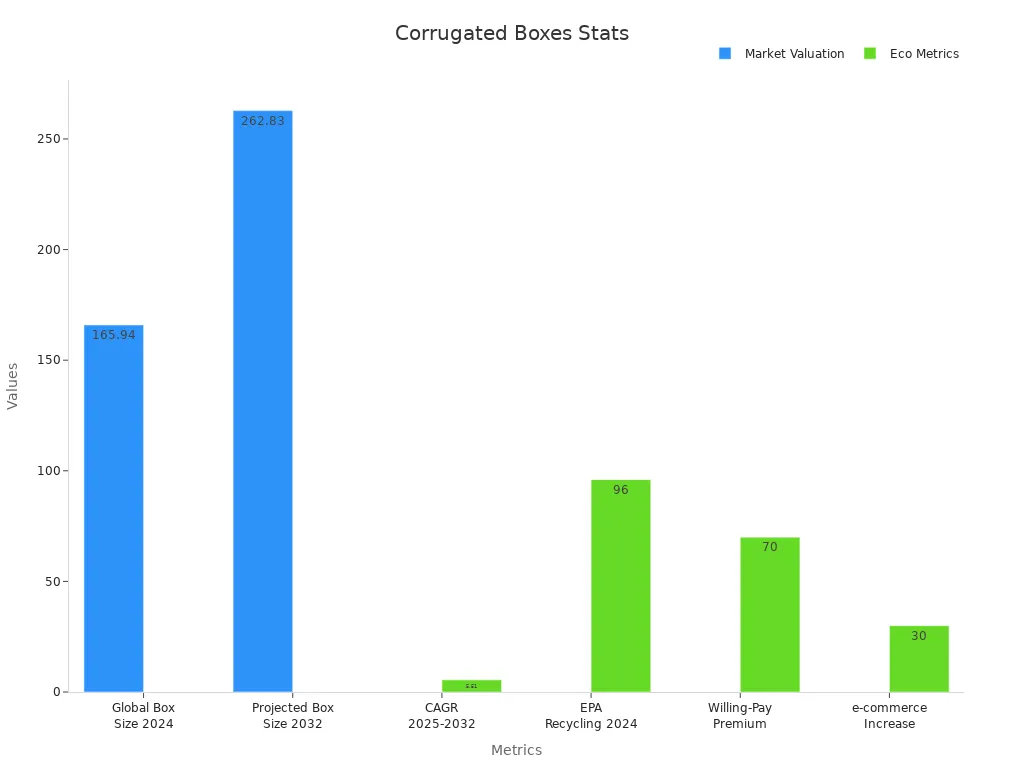

The global market for corrugated shipping boxes is worth over $171 billion in 2024.

About 91.4% of corrugated material in the U.S. is recycled each year.

Lightweight designs help lower shipping costs and cut down carbon emissions.

Key Takeaways

Corrugated shipping boxes have three layers. These layers make them strong. They help protect things during shipping. There are different types of boxes. Some are single wall, double wall, or triple wall. There are also die-cut boxes. Each type gives different strength and protection. These boxes are used in many industries. People use them for food, electronics, medical, cars, and online shopping. The boxes are strong and soft inside. They are light, so shipping costs less. This also helps the environment. Most corrugated boxes use recycled materials. They come from forests that are managed well. This makes them good for the earth. Picking the right box size and strength is important. It keeps products safe and saves money on shipping. Custom boxes can help people remember your brand. They can also make customers happy. But custom boxes may cost more. They can also take longer to make. It is important to pick a good supplier. A good supplier gives quality boxes and good help. This makes sure you get the best boxes for your needs.

1. Corrugated Shipping Boxes Overview

Structure

Corrugated shipping boxes are special because they have three layers. There are two flat linerboards on the outside. The middle layer is a wavy fluted medium. This design makes the box strong. It also helps keep your things safe when shipping.

Linerboard

The linerboard is on the outside of the box.

It gives a smooth surface for printing and labels.

Strong paper like Kraft paper is used for linerboards.

Linerboards help stop the box from bending or crushing.

Fluted Medium

The fluted medium is between the linerboards.

It looks like waves or zigzags.

This layer gives padding and soaks up shocks.

Flutes come in sizes like A, B, C, and E. Each size gives a different level of protection.

Tip: Linerboard and fluted medium together make corrugated shipping boxes much stronger than regular cardboard boxes.

Materials

Manufacturers use different papers and coatings to make these boxes:

Kraft paper: Very strong and hard to tear, often used for linerboards.

Test liners: Made from recycled paper, good for saving money.

Chip liners: Lower quality, made from recycled stuff.

Semi-chemical flutes: Give the box high strength against pressure.

Coatings: Some boxes have waterproof, scratch-proof, or sun-blocking coatings.

Manufacturers pick materials based on what the box will hold. For example, boxes for electronics may need special coatings. Food boxes may need to be waterproof.

Comparison

You may ask how corrugated shipping boxes are different from regular cardboard boxes. The table below shows the main differences:

Note: Corrugated shipping boxes protect your things better and last longer. That is why people use them most for shipping and storage.

2. Types

When you pick corrugated shipping boxes, you will see a few main types. Each type gives a different amount of strength and protection. Manufacturers make these boxes for special shipping needs. Here are the most common types you will find:

Single Wall

Single wall corrugated shipping boxes are the most used for daily shipping. These boxes have one fluted medium layer between two linerboards. This design gives good strength and keeps the box light. Most companies use single wall boxes for groceries, clothes, and dry goods.

The board test rating is 44 ECT (Edge Crush Test).

These boxes can hold up to 95 pounds. The wall is about 3/16 inch thick.

The C flute profile is common. It gives both padding and stacking strength.

Single wall boxes are fully recyclable and meet ASTM D5118 rules.

Note: About 65% of shipments use single wall boxes. They are everywhere because they cost less and are easy to recycle.

Double Wall

Double wall corrugated shipping boxes are stronger than single wall. These boxes have two fluted medium layers and three linerboards. You should use double wall boxes for heavier or fragile things.

Double wall boxes pass tough tests like the Mullen Test and Edge Crush Test.

These boxes do not crush or get holes easily. They can handle stacking pressure.

You can stack them higher in warehouses without worry.

Many companies add coatings to stop water or grease.

Tip: Double wall boxes are great for electronics, machine parts, and bulk food. You can trust your items will stay safe on long trips.

Triple Wall

Triple wall corrugated shipping boxes give the most protection. These boxes have three fluted medium layers and four linerboards. You should use triple wall boxes for the heaviest or most valuable items.

Triple wall boxes are very strong and hard to puncture.

Many have extra strong corners and waterproof coatings.

These boxes are used in food, electronics, and medicine industries.

The heavy-duty corrugated box market is growing fast. It may reach $15 billion by 2025.

Note: Triple wall boxes are best for shipping big machines, export goods, or anything that needs the most protection.

Die-Cut

Die-cut boxes are not just plain boxes. Special machines cut and fold them into many shapes. You can get boxes with handles, windows, or special openings. Some boxes have custom inserts to hold items in place. These boxes are good for products that need extra care or a cool look.

You can buy die-cut boxes for food, electronics, makeup, and store items.

Many online shops use die-cut mailers for a fun unboxing.

Die-cut boxes can have snap-locks, magnets, or sliding parts.

Boxes made to fit your product help you use less packing stuff.

Makers now use green materials like recycled paper and bioplastics.

New printing and materials let you add logos, colors, and pictures.

Note: In March 2024, Kite Packaging in the UK made a tool. It lets you pick the size, board type, and color for your die-cut box. You get prices right away and fast making. Antalis Packaging and Ezee Group made an egg box. It packs eggs 75% faster and uses 20% less material. Mukund Corrupack in Hyderabad made twice as many boxes in 2023. They used new machines and printed boxes themselves.

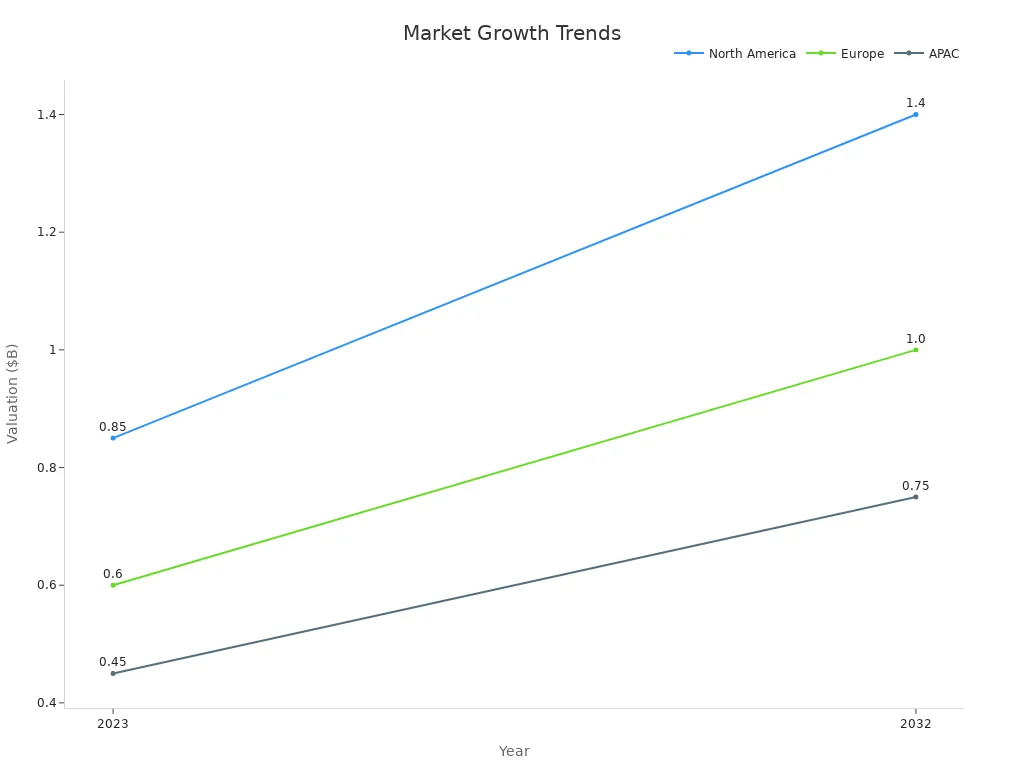

The die-cut box market is getting bigger. You see new box styles for food, electronics, and medicine. Online shopping makes people want boxes that fit well and look nice. North America uses the most die-cut boxes. Europe and Asia are using more each year. More companies use recycled and green materials to help the planet.

Custom Options

Custom options let you make boxes that fit your brand and product. You can work with a maker to pick the size, shape, color, and finish. Custom boxes help your brand stand out and keep your things safe.

You can add raised logos, special inserts, or coatings for more safety.

Custom boxes use green materials to help the earth.

You get to choose how your box looks and feels.

Custom boxes cost more and take longer to make, but they help your brand and make customers happy.

Tip: Talk to your box maker about the best custom features. You can make your brand stronger and keep your products safe at the same time.

3. Uses

Industries

You can find corrugated shipping boxes in many industries. Companies use these boxes to keep products safe. Here are some main industries that use them:

Food and Beverage: This group uses more than half of all heavy-duty boxes. You see these boxes in stores, restaurants, and food delivery.

Electronics: Makers use strong boxes to ship computers and phones. Double wall boxes protect fragile things from bumps.

Pharmaceuticals and Medical Devices: Hospitals and labs use these boxes for medicine and equipment.

Automotive and Industrial: Heavy parts and machines need strong boxes. Double or triple wall boxes give extra strength.

E-commerce and Retail: Online shops use custom boxes for clothes, books, and electronics. These boxes help brands look special and keep items safe.

Personal Care and Household Products: Soap, shampoo, and cleaners often come in these boxes.

Note: Research shows processed food is the biggest user, making up 25% of sales in 2023. Asia-Pacific is the top market, with 55% of global sales.

Products

You can pack almost anything in corrugated shipping boxes. Makers design boxes for many products:

Fresh and Processed Foods: Fruits, snacks, and frozen meals stay safe and fresh.

Beverages: Bottled drinks and juice boxes travel in strong boxes.

Glassware and Ceramics: Fragile dishes and glasses need extra care.

Consumer Electronics: Phones, laptops, and TVs ship in custom boxes.

Textiles and Apparel: Clothes and shoes arrive in light, stackable boxes.

Personal and Home Care: Soap and toothpaste use boxes for bulk shipping.

Chemicals and Pharmaceuticals: Medicines and lab supplies need water-resistant boxes.

Tip: In Western Europe, Germany and France lead in using these boxes for food and goods. About 80% of boxes in France are recycled, showing a big focus on the environment.

Shipping & Storage

Corrugated shipping boxes are important for moving and storing things. You can use them for shipping, storage, and online shopping. Makers create boxes that fit products well and cut down waste. This saves money and keeps goods safe.

Companies use special software to make boxes that fit just right.

Mushroom-based boxes are now used for green shipping.

The McKee Formula helps pick the right box strength for stacking.

Online shopping needs boxes that are light and strong.

Food and drink companies use water-resistant boxes to keep things fresh.

Callout: In 2024, DS Smith made a recyclable box for grocery shipping. Saica Group and Mondelez International made heat-sealable boxes for cookies. These new ideas show how makers change boxes for new shipping and storage needs.

You can see that corrugated shipping boxes help deliver things safely, store them well, and support green practices in many industries.

4. Benefits

Strength

Engineered for High Strength

These boxes are made to be very strong. They can handle tough shipping and storage. Makers use special tests to check each box. They use static compressive strength analysis and dynamic load simulation. These tests show if the box can hold heavy things and take rough handling.Tested for Real-World Conditions

Makers do Box Compression Tests and Edge Crush Tests. These tests check how much weight a box can take. Vibration tests show how boxes do during transport. These tests prove your box will not crush or break easily.Customizable Strength Levels

You can pick boxes with single, double, or triple wall. Each type gives a different strength. Makers change the thickness, liner type, and flute size. This helps match the box to your needs.

Tip: Perforations, openings, or flaps can change how much weight your box can hold. Always ask your maker for the best design.

Lightweight

Efficient Shipping

Lightweight boxes help you save money on shipping. You can move more things at once. The boxes do not add much weight. This makes shipping easier and faster.Strong Yet Light

Even the lightest single-wall boxes can hold up to 20 pounds. You get good protection without heavy boxes. Makers design these boxes to balance weight and strength.

Eco-Friendly Shipping

Using lighter boxes means less fuel is needed. This creates fewer emissions. It helps your business meet green goals and saves money.

Note: Studies show lightweight boxes, like 32 ECT, lower shipping costs. They also use less material but still protect lighter goods.

Protection

Superior Cushioning

These boxes give great protection for fragile things. Makers use memory foam, air cushions, and bio-based inserts. These help absorb shocks from bumps and drops.Smart Design Features

Boxes have strong corners, many layers, and custom inserts. These features stop your things from moving inside the box. The design spreads out impacts and keeps items safe.Tested for Safety

Drop tests and vibration tables check box safety. These tests make sure your box meets the latest rules for fragile items.Clean and Sustainable

Your packaging stays clean and easy to use. Makers use renewable and recyclable materials. This protects your things and helps the environment.

Callout: Studies show corrugated boxes are both strong and soft. This keeps heavy or fragile items safe during shipping and storage.

Eco-Friendly

You want packaging that is good for the planet. Corrugated shipping boxes are known for being eco-friendly. Here are the main reasons you can trust them for green packaging:

Certified Sustainable Materials

Many makers use paper from forests that are well cared for. These forests are checked by groups like the Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI). These groups make sure forests are safe for nature, workers, and people nearby.High Recycled Content

Most boxes have a lot of recycled paper inside. Makers use old boxes, mixed paper, and newspapers. This means fewer new trees are cut down and less energy is used.Strong Recycling Systems

The industry works hard to make recycling better. You see more bins and better sorting at stores and homes. This keeps boxes out of landfills and lets them become new packaging.Market Demand for Recycled Fibers

More companies want recycled materials now. This makes makers use even more recycled paper. It helps lower harm to the environment.Reduced Landfill Waste

When you recycle these boxes, you help keep trash out of landfills. Some cities and companies even turn boxes into soil by composting.Education and Policy Support

Schools, businesses, and governments teach people how to recycle right. Better rules and programs help make recycling work well.

Tip: Check your boxes for FSC or SFI logos. These marks mean you picked packaging that helps forests and supports good sourcing.

5. Choosing Corrugated Shipping Boxes

Identification

When picking corrugated shipping boxes, you must find the right type. First, look at what you want to ship. Think about how big, heavy, or breakable your items are. You need a box that keeps your things safe.

Check the contents: If your items are heavy or break easily, use stronger boxes. Lighter or soft things can go in lighter boxes.

Review the shipping process: If your package will be moved a lot or shipped far, pick a box that is tougher.

Consider your budget: Thicker boxes do not always weigh more. Try to save money but still protect your items.

Think about branding: If you want your logo or colors on the box, ask the maker about printing and paper.

Work with experts: Packaging experts and makers can help you pick the best box and materials.

Tip: Always ask your maker about custom choices. You can get boxes in many styles, thicknesses, and with green materials like recycled paper or FSC® certification.

You should also check for quality tests. Good makers test boxes for strength and toughness. Here is a table of common tests:

Sizing

Getting the right size for your corrugated shipping boxes is very important. You want a box that fits your product and keeps it safe.

Measure your product: Use a tape to find the length, width, and height. Always measure inside the box flaps for the best fit.

Record in inches: Write down your numbers in inches. This helps you stay clear and not make mistakes.

Calculate dimensional weight: Multiply length, width, and height. Divide by the carrier’s number (like 139 for UPS or FedEx). This helps you know the shipping price.

Choose standard or custom sizes: Standard sizes are easy to get and cost less. Custom sizes are better for odd shapes or breakable things.

Check carrier rules: Each shipping company has size and weight rules. Make sure your box fits so you do not pay extra.

Note: Do not forget about box thickness or mix up length and width. Always leave room for padding if your item needs more protection.

Strength Rating

You need to pick a box with the right strength for your shipment. Makers use tests to rate how strong a box is. These ratings help you match the box to your item’s weight and shipping needs.

Edge Crush Test (ECT): Checks how much pressure the box edge can take. For light things, 32 ECT is normal. For heavy things, use 44 ECT or more.

Mullen Burst Test: Shows how much force it takes to break the box wall. Most shipping uses 200#, but heavy things need 275# or more.

Box Compression Test (BCT): Tells you how much weight a box can hold when stacked. This is important for storage in warehouses.

Cobb Water Absorption Test: Checks how much water the box soaks up. Use this for things that need to stay dry.

Callout: Double-wall or triple-wall boxes are best for breakable or big items. Ask your maker about the best flute type and paper for your needs.

Picking the right corrugated shipping boxes means looking at your item, measuring well, and checking strength ratings. Work with your maker to get the best box for your shipments.

Supplier Options

When picking a supplier for shipping, you want someone you can trust. You also want good quality and helpful support. There are many choices, so it is smart to know what matters most. Here are some important things to think about when picking a manufacturer or supplier:

Reputation and Experience

Pick suppliers who have been around for a long time. If a company has many years in business, it means they know what they are doing. Companies like South Bend Packaging and WestRock have earned trust over the years. Customer stories, like Judy Peterson’s 30 years with PRC, show they give good service and deliver on time.Quality Assurance and Certifications

Choose a manufacturer with industry certifications like ISO. These show they care about high standards. Awards also mean they work hard for quality. Many suppliers let you try samples or test boxes first. This way, you can see if the boxes fit and work before you buy a lot.Customization and Problem-Solving

Sometimes your products need special packaging. The best suppliers can make boxes in custom sizes and shapes. They can add features you need. Some case studies show how they fix tough packaging problems. You can ask for inserts, coatings, or green materials to fit your needs.Bulk Ordering and Cost Savings

Many suppliers give discounts if you buy a lot at once. Buying in bulk saves money and makes sure you have enough boxes when it gets busy. Good materials keep your items safe and lower the chance of damage.Eco-Friendly Solutions

Today, many suppliers care about the environment. You can get boxes with recycled content or FSC certification. Some use green materials and ways of making boxes to help you meet your earth-friendly goals.Local Availability and Fast Shipping

Local centers, like those in Denver, Colorado, can deliver boxes quickly. Fast help and answers make it easy to fix problems. Suppliers like Boxes 4 U and Arizona Corrugated Container give local service and quick orders.Comprehensive Services

Some suppliers, like Union FAS, do more than just sell boxes. They can help design your packaging, ship your products, and even set things up. This saves you time and helps your products arrive safely.

Tip: Always read reviews and look at case studies before you pick a manufacturer. Good suppliers answer your questions about protection, custom options, strength, and price. They give you quality, fast delivery, and great support.

There are lots of supplier choices for your packaging. If you focus on these things, you can find a manufacturer who gives you good quality, value, and peace of mind.

Corrugated shipping boxes are strong and light.

They are good for the environment too.

Makers use recycled materials and new technology.

This helps make boxes tough and earth-friendly.

These boxes protect food, electronics, and store items.

They also help cut down on waste.

More people want these boxes in many places.

Pick the best box and maker to keep your things safe, help your brand, and care for the earth.

FAQ

What makes corrugated shipping boxes different from regular cardboard boxes?

Corrugated shipping boxes have three layers. This makes them stronger than regular cardboard. They protect your things better. These boxes are made for shipping and storage. You can trust them to keep items safe.

Can you recycle corrugated shipping boxes?

Yes, most corrugated shipping boxes can be recycled. Many new boxes use recycled materials. Look for recycling signs or FSC marks on the box. Recycling helps cut down waste and keeps the supply chain green.

How do you choose the right size box for your product?

First, measure your product’s length, width, and height. Add a little extra space for padding. You can pick from standard or custom sizes. The right size box keeps your items safe and saves money on shipping.

What strength rating should you look for in a shipping box?

Check the Edge Crush Test or Mullen Burst Test rating. Pick a higher rating for heavy or breakable things. Manufacturers can help you choose the right strength for your needs.

Are custom corrugated shipping boxes worth the extra cost?

Custom boxes make your brand easy to spot. You can choose the size, shape, and design you want. Some boxes have special coatings or inserts. Custom boxes cost more but give better protection and branding.

How fast can a manufacturer deliver corrugated shipping boxes?

How fast you get boxes depends on your order and custom choices. Standard boxes ship quickly from many makers. Custom boxes take longer to make and send. Ask your manufacturer how long it will take before you order.

What industries use corrugated shipping boxes the most?

Food, electronics, e-commerce, and car companies use these boxes a lot. Manufacturers make boxes for many products. These boxes keep goods safe during shipping and storage in many industries.

Tip: Always talk to your manufacturer about what you need. This helps you get the best corrugated shipping boxes for your business.