When I think about what makes a luxury paper box factory stand out, advanced machinery immediately comes to mind. These machines ensure precision and durability while allowing for unique customization. For example, the Jialite Automatic Laminating Machine applies eco-friendly films with perfect adherence, while UV coating machines protect boxes from scratches and moisture, ensuring premium packaging quality.

Key Takeaways

High-tech machines, like laminators and die-cutters, make packaging stronger and more attractive, drawing in buyers.

Automation speeds up work, cuts down hand labor, and boosts efficiency. This helps factories finish on time while keeping quality high.

Custom tools let factories make special designs that build brand image. This makes packaging a key part of the buyer's experience.

Key Machinery in a Luxury Paper Box Factory

Laminating Machines for Durability and Aesthetic Appeal

Laminating machines play a vital role in enhancing both the durability and visual appeal of luxury packaging. I’ve seen how these machines apply protective films to paper boxes, making them resistant to moisture and scratches. This process not only extends the lifespan of the packaging but also adds a premium finish that attracts consumers. For instance, the global flexible packaging market, valued at $269.9 billion in 2022, highlights the growing demand for laminating machines. With the rise of e-commerce, especially in Asia-Pacific, durable and visually appealing packaging has become a necessity.

Die-Cutting Machines for Precision and Custom Shapes

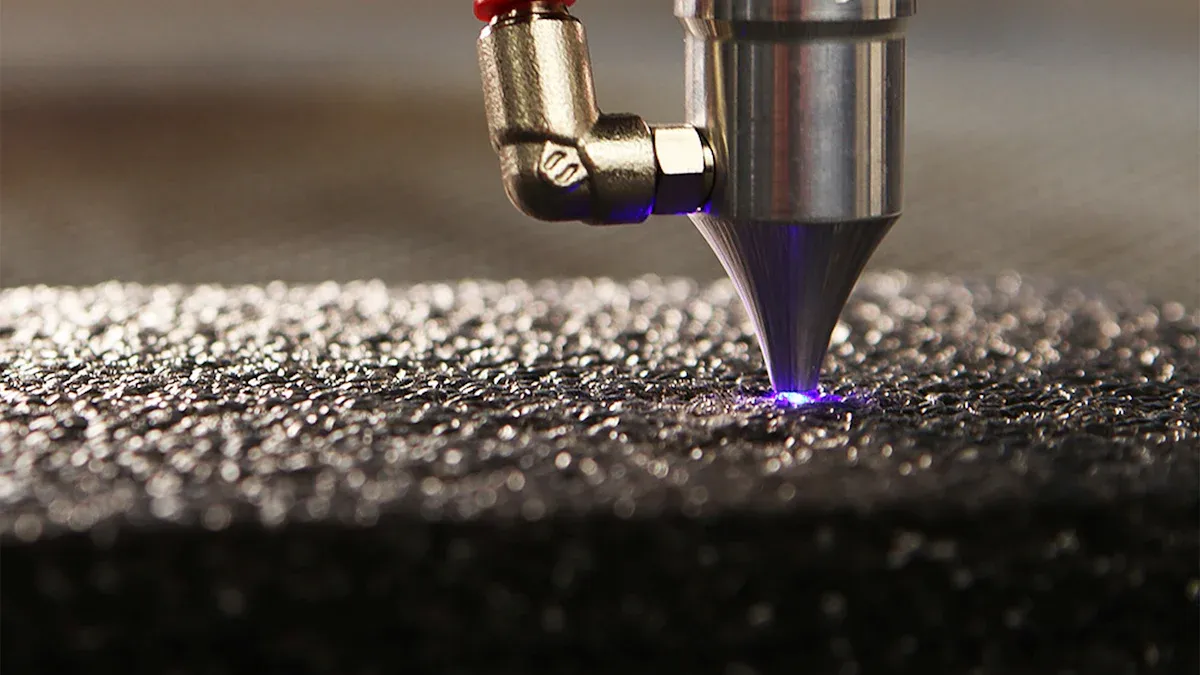

Die-cutting machines are essential for creating custom shapes and designs in the box manufacturing process. These machines ensure precise cuts, which are crucial for maintaining the quality of luxury boxes. I’ve noticed that advanced die-cutting machines, equipped with CNC driving systems and electric eye sensors, deliver unmatched accuracy. For example, a die-cutting precision of 0.05mm guarantees clean edges, even for intricate designs. This level of precision is indispensable for producing high-quality packaging solutions tailored to specific client needs.

Embossing Machines for Texture and Elegance

Embossing machines add texture and elegance to packaging, making it stand out on store shelves. I’ve read studies showing that tactile elements in packaging can increase consumer engagement by up to 15%. These machines create raised patterns or logos, giving the boxes a luxurious feel. Research also indicates that embossed finishes enhance shelf impact, influencing purchase decisions in competitive markets. This makes embossing an invaluable step in the box manufacturing process.

Hot Stamping Machines for Metallic and Foil Accents

Hot stamping machines bring metallic and foil accents to life, elevating the aesthetic appeal of luxury packaging. I’ve seen how foil decoration can boost purchase rates by 40% compared to traditional printing. These machines use heat and pressure to transfer metallic foils onto the surface of boxes, creating eye-catching designs. Positive eye-tracking results, improved by up to 80% with foil accents, further demonstrate the effectiveness of this technique in capturing consumer attention.

Quality Control Equipment for Consistency and Standards

Maintaining consistency and adhering to quality standards are non-negotiable in a top-tier paper box factory. Quality control equipment ensures that every box meets the required specifications. I’ve observed that regular calibration of measuring devices and standardized measurement procedures are critical for achieving this. By implementing a robust quality control system, factories can monitor equipment performance, document procedures, and take corrective actions when necessary. This guarantees that the final packaging solutions align with client expectations.

Advanced Technology in Top-Tier Machinery

Automation for Streamlined Production

Automation has revolutionized the way luxury paper boxes are manufactured. I’ve seen how automated box making systems reduce manual labor while increasing production speed. These systems handle repetitive tasks with precision, allowing workers to focus on more creative aspects of the process. For example, predictive maintenance in automated machinery can reduce downtime by up to 45% and extend equipment life by 20-40%. This ensures uninterrupted production and long-term cost savings.

Here’s a quick look at how automation improves manufacturing efficiency:

These features make automation an essential part of any top-tier factory. It not only streamlines production but also ensures consistent quality in every batch.

Precision Engineering for Superior Quality

Precision engineering is the backbone of high-quality luxury packaging. I’ve noticed how advanced technology ensures every box meets strict standards. Metrics like GSM (grams per square meter) and PT (points) are critical for determining material strength and durability.

GSM ensures the packaging material is robust and heavy-duty, ideal for luxury items.

PT values are crucial for products that need thicker, sturdier materials to prevent damage.

Understanding these metrics helps businesses balance cost, durability, and aesthetics.

By focusing on these features, manufacturers can deliver packaging that meets customer expectations while maintaining high performance.

Customization Capabilities for Unique Designs

Luxury packaging thrives on uniqueness. I’ve observed how advanced technology enables factories to create custom designs that stand out. Automated box making systems allow for intricate patterns, embossing, and foil stamping, all tailored to client specifications. This level of customization not only enhances the visual appeal but also strengthens brand identity.

For instance, a client might request a specific texture or metallic finish to align with their branding. With the right machinery, these requests are easily fulfilled. Customization features like these ensure that every box tells a story, making it more than just packaging—it becomes an experience.

Benefits of Using Advanced Machinery in a Paper Box Factory

Enhanced Production Efficiency

I’ve observed how advanced machinery transforms production efficiency in a paper box factory. Automated systems streamline repetitive tasks, reducing manual intervention and speeding up the manufacturing process. This allows factories to produce more boxes in less time while maintaining consistent quality.

The implementation of advanced machinery and AI tools in manufacturing has led to a 40% increase in overall output. Self-learning AI eliminates inspection requirements, further enhancing operational efficiency.

To better understand how machinery impacts efficiency, consider these key performance indicators:

These advancements ensure that factories meet tight deadlines without compromising on quality.

Consistent High-Quality Output

Maintaining high standards is essential for producing high-quality boxes. I’ve seen how advanced machinery ensures consistency by integrating precise control systems. For example, real-time monitoring platforms allow operators to oversee every step of the process, ensuring that each box meets the required specifications.

These features guarantee that every box produced aligns with the high standards expected in luxury packaging.

Meeting the Demands of the Luxury Market

Luxury packaging demands precision, durability, and aesthetic appeal. Advanced machinery enables factories to meet these requirements by offering customization options and superior finishes. I’ve noticed how embossing, foil stamping, and laminating machines create visually stunning boxes that resonate with premium brands.

Sustainability also plays a crucial role in the luxury market. Many factories now use eco-friendly materials and processes to reduce environmental impact. For instance, corrugated boxes in packaging are gaining popularity due to their recyclability and strength. By adopting advanced machinery, factories can produce sustainable packaging solutions without sacrificing quality or efficiency.

Investing in advanced machinery transforms a paper box factory into a leader in luxury packaging. I’ve seen how AI-driven technologies enhance efficiency, reduce labor costs, and improve quality. File comparison software ensures precise inspections, minimizing risks. These innovations meet the market’s demand for sustainability and innovation, securing a competitive edge.

FAQ

What makes laminating machines essential in luxury packaging?

Laminating machines enhance durability and aesthetics. They apply protective films that resist moisture and scratches, ensuring the boxes maintain their premium look over time.

How does automation improve production efficiency?

Automation reduces manual labor and speeds up repetitive tasks. It ensures consistent quality, minimizes errors, and allows factories to meet tight deadlines with ease.

Tip: Automated systems with predictive maintenance can significantly reduce downtime, saving costs and boosting productivity.

Why is embossing important for luxury paper boxes?

Embossing adds texture and elegance. It creates raised patterns or logos, making the packaging visually appealing and tactile, which enhances consumer engagement.