The price of corrugated boxes in 2025 depends on various factors. Fluctuating costs of pulp and paper directly impact profits, while challenges in the supply chain make materials harder to obtain. Additionally, rising shipping costs contribute to these complexities. With increasing demand for eco-friendly packaging, the situation becomes even more intricate. At YiXin Printing, a trusted paper box factory, I focus on innovative solutions to address these challenges and ensure competitive paper box supply at affordable prices.

Key Takeaways

The cost of materials changes box prices. Watch pulp and paper costs to predict changes.

Problems in the supply chain can raise packaging costs. Good planning and teamwork help handle these problems.

More people want eco-friendly packaging now. Companies should use green materials to please customers and follow rules.

Material Costs and Supply Chain Dynamics

Raw Material Prices and Their Impact on Cost

The price of raw materials affects how much cardboard costs. Changes in pulp and paper prices can raise packaging costs. For instance, in July 2024, corrugated boxes cost 878 USD per square meter (FOB). By August 2024, the price rose to 895 USD per square meter. In India, prices went from 803 USD in January 2024 to 867 USD by June 2024. These changes show how raw material prices impact cardboard packaging costs.

Supply Chain Disruptions in the Paper Box Supply Industry

Problems in the supply chain make getting materials harder. Delays in moving raw materials increase packaging costs. Issues like crowded ports or not enough workers reduce cardboard supply. When supply is low, prices go up, making boxes cost more to make. Fixing these problems needs good planning and teamwork in the supply chain.

Freight and Transportation Costs in the Corrugated Cardboard Market

Shipping costs have gone up, affecting cardboard prices. A 12% rise in transport costs, caused by higher fuel prices, adds to packaging expenses. Crowded ports make things worse and delay material delivery. These issues raise costs and slow down supply. Using better routes and eco-friendly methods can help lower these costs.

Economic and Political Influences

Inflation and Its Effect on Paper Box Factory Operations

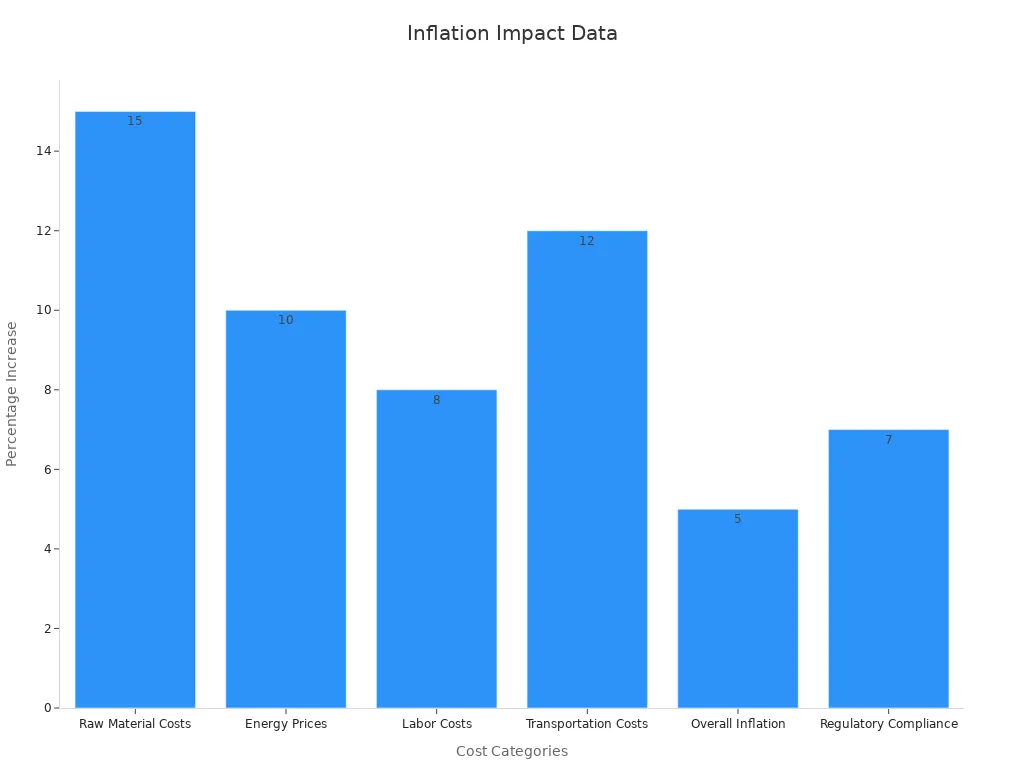

Inflation makes running paper box factories more expensive. Prices for materials, energy, and labor keep rising. For example, material costs went up by 15%. Energy prices increased by 10%, and labor costs grew by 8%. These higher costs make it hard to keep prices low. Below is a table showing how inflation affects different costs:

This table shows how inflation raises the cost of making paper boxes. It also impacts the entire supply chain.

Trade Policies and Their Role in Pricing

Trade rules affect how much paper boxes cost. Taxes on imported materials make production more expensive. For example, higher taxes on pulp imports raise costs for factories. Some countries also limit exports of key materials, which increases prices. To handle these changes, factories need smart planning and better resource use.

Geopolitical Events and Their Impact on Global Paper Box Supply

World events can disturb the paper box supply. For example:

Bret Biggers, an economist, said the Red Sea crisis caused delivery delays and higher prices for U.S. exports to Asia.

Edith Leeuta, CEO of Fibre Circle, explained how global tensions raised transport costs and reduced fiber supplies.

These problems make prices harder to predict. To manage this, I work with reliable suppliers and find new sources for materials.

Laws and Trends in Sustainable Packaging

Environmental Rules and Their Effect on Costs

Governments are making stricter rules to protect nature. These rules require packaging to be recyclable and biodegradable. While good for the planet, they raise production costs. Factories need new materials and methods to follow these rules. This change affects the industry a lot. Adjusting to these laws takes smart planning and new ideas.

Rising Demand for Eco-Friendly Cardboard Packaging

People now care more about the environment. They want products with green packaging. This has increased the need for recyclable materials. Businesses now focus on eco-friendly packaging to please customers. Factories must find ways to stay green and keep costs low. Balancing both needs creative thinking and smart resource use.

Costs of Following Environmental Laws for Factories

Obeying green laws costs money. Factories must buy better tools, train workers, and use eco-friendly materials. These costs can be hard for small factories. Planning ahead helps save money over time. It also makes factories leaders in green packaging. This is good for both business and the planet.

Technological Advancements in the Corrugated Cardboard Industry

Automation and Its Role in Reducing Costs

Automation has changed how packaging is made. Machines now work faster and waste less. For example, tracking systems help factories use fewer materials. Better planning speeds up production and saves money. Factories also manage supplies better, so they don’t buy too much.

Here’s how automation helps save money:

These tools help make strong boxes for less money. This keeps businesses competitive.

Innovations in Corrugated Cardboard Design

New designs are changing cardboard packaging. Many factories now use eco-friendly materials. These designs are strong and look good too. They protect items better during shipping.

Using less material also saves money. For example, thinner but stronger cardboard needs fewer resources. This helps businesses spend less and care for the planet. It also meets the growing need for recycled packaging.

Digital Printing and Its Impact on Cost Optimization

Digital printing has made packaging easier and cheaper. Software now handles many tasks, saving time and money. It connects with factory systems to plan work better.

Digital printing doesn’t need special plates like old methods. This means factories can print only what they need. It reduces waste and extra costs. Inkjet printing is growing fast because it works well. These changes make making cardboard packaging faster and cheaper.

Consumer Demand and Market Trends

E-commerce Growth and Its Influence on Paper Box Supply

Online shopping is changing how businesses work. This growth affects packaging needs. The e-commerce packaging market might grow from $90.8 billion in 2025 to $272.77 billion by 2034. It could grow 13% each year. More online shopping means more demand for good packaging. Cardboard boxes are popular because they are eco-friendly.

As people shop online, they want strong and green packaging. Big online stores now use less plastic and more paper-based boxes. This change meets customer needs and follows new rules. I think this trend will make cardboard even more important. It will push factories to create better packaging and supply more boxes.

Shifting Preferences for Sustainable Packaging Solutions

People care about the environment more now. Many choose green packaging instead of regular options. In 2021, the U.S. made 40 million tons of plastic waste. Only 5% to 6% of it got recycled. But paper recycling reached 68% in 2022. Most recycled paper is used to make cardboard.

This change in what people want makes companies use eco-friendly materials. Governments also make stricter rules to cut down on plastic use. These rules push businesses to focus on green packaging. This increases the need for recyclable cardboard. I think this trend will keep growing and shape packaging in the future.

Regional Market Trends in Corrugated Cardboard Pricing

Cardboard prices are different in each area. On the West Coast, prices for 32 ECT C-flute sheets went up 4-6%. This added $40 per ton. In the South, prices stayed steady because of competition, even with delays. Export markets are slow, which helps keep U.S. prices stable.

Costs are rising everywhere because of higher labor, shipping, and material expenses. These regional differences show how tricky the cardboard market is. By knowing these trends, I can handle challenges better. This helps me keep a steady supply of boxes for my customers.

The price of corrugated boxes in 2025 depends on many things. Material costs, laws, new technology, and customer needs all matter. These factors work together and raise costs in the supply chain. I focus on recycling cardboard and using smart ideas to save money. At YiXin Printing, I provide green solutions and meet the need for eco-friendly packaging.

FAQ

What are the main packaging trends for 2025?

Eco-friendly packaging is becoming very popular. Recyclable materials and creative designs are in demand. These trends match global goals to protect the planet and what people want.

How does online shopping change packaging needs?

Online shopping increases the need for strong, green packaging. Companies now use recyclable materials to make customers happy. This also fits with 2025 packaging trends.

Why is eco-friendly packaging important?

Eco-friendly packaging helps keep the planet healthy. Recyclable materials cut down on waste and support global green goals. It also meets the rising need for planet-friendly packaging.