Comprehensive Guide to Printing and Packaging

1. Understanding Paper Weight and Thickness

What is Paper Weight?

Paper weight is measured in grams per square meter (gsm). For example, 80gsm means that one square meter of the paper weighs 80 grams. The thickness of paper is usually measured in microns, which can be determined using a micrometer.

Choosing the Right Paper Weight for Different Products:

- Premium Gift Boxes : For gift boxes or hardcover books, the outer paper should ideally be between 110gsm to 160gsm. Coated paper should be laminated to prevent tearing and ink smudging.

- Paper Bags : Paper bags should use paper between 200gsm to 300gsm for better durability. Coated paper and white cardstock should be laminated to avoid tearing.

- Brochures and Catalogs : For image-heavy brochures, coated paper is recommended for vibrant colors. The cover should be between 200gsm to 350gsm, while inner pages can range from 80gsm to 200gsm.

- Color Boxes : Color boxes can use both coated and uncoated paper. Coated paper typically ranges from 250gsm to 400gsm, while uncoated paper ranges from 150gsm to 250gsm.

2. Structural Design of Color Box Packaging

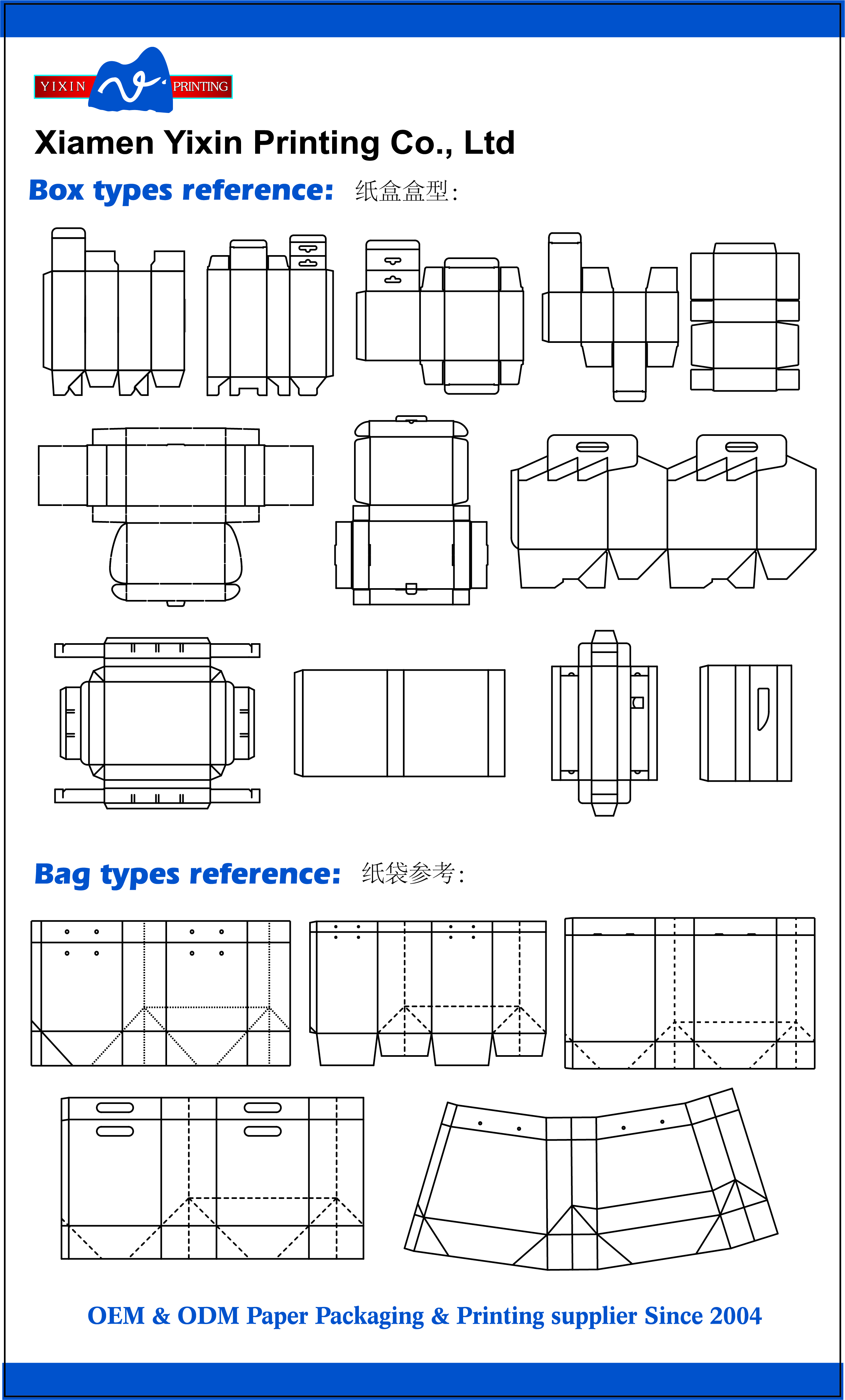

Tubular Packaging Structure Design

Tubular packaging is one of the most common types of packaging, especially for consumer goods. The design focuses on ease of assembly and opening while ensuring product protection.

# Lid Structures:

1. Insert Flap Type : The lid has three flaps, with a main flap that extends to insert into the box. This is the most widely used lid structure.

2. Lock Type : The front and back flaps interlock, providing a secure seal, though assembly and opening can be slightly more complicated.

3. Insert Lock Type : Combines insertion and locking for a more secure closure.

4. Double Insurance Insert Type : Provides a double-lock mechanism, making it very secure and suitable for repeated use.

5. Adhesive Seal Type : Offers excellent sealing but is not reusable, ideal for powdered or granular products.

6. One-Time Anti-Counterfeit Type : Features a perforated tear line to prevent reuse, commonly used in pharmaceutical and small food packaging.

7. Press Seal Type : Utilizes the paper's flexibility for easy assembly and opening, ideal for small product packaging.

8. Continuous Flap Interlocking Type : Highly decorative but more complex to assemble, often used for gift packaging.

# Bottom Structures:

1. Self-Locking Bottom : Uses interlocking flaps for easy assembly and good weight-bearing capacity.

2. Automatic Lock Bottom : Pre-glued for easy assembly and strong weight-bearing, suitable for automated production.

3. Double Insert Flap Bottom : Simple to use but has lower weight-bearing capacity, ideal for lightweight products.

4. Partitioned Bottom : Creates internal partitions to protect and separate products, offering high compressive strength.

Tray Packaging Structure Design

Tray packaging is commonly used for textiles, clothing, and food products. The main structural variations are in the body, with the bottom remaining relatively unchanged.

# Main Assembly Methods:

1. Insert Assembly : No glue or locks, easy to use.

2. Lock Assembly : Provides a more secure structure.

3. Pre-Glued Assembly : Simplifies the assembly process.

# Main Structures:

1. Cover Type : Consists of two independent tray structures that fit together, commonly used for clothing and footwear.

2. Flap Type : Features an extended flap on one side, similar to tubular packaging.

3. Continuous Insert Type : Similar to the continuous flap interlocking type in tubular packaging.

4. Drawer Type : Comprises a tray and an outer sleeve.

5. Book Type : Opens like a hardcover book, often used for high-end packaging.

---

3. Printing Knowledge Q&A

Why is FSC-COC Certification Important?

FSC-COC certification ensures that wood products come from responsibly managed forests. It is a globally recognized standard that enhances a company's reputation, helps win more orders, and reduces market entry risks.

What are the Key Processes in Printing and Packaging?

1. Pre-Press : Includes design, typesetting, and plate making.

2. Press : The actual printing process.

3. Post-Press : Includes binding, laminating, cutting, and quality inspection.

What is Soy Ink?

Soy ink is an eco-friendly alternative to traditional petroleum-based inks. It is made from soybeans, offering vibrant colors, high gloss, and excellent stability. It is also biodegradable and safer for the environment.

What are Specialty Papers?

Specialty papers are used for premium printing applications like business cards, invitations, and luxury packaging. They often feature unique textures, patterns, or finishes that set them apart from standard papers.

What is ISO9001 Certification?

ISO9001 is a quality management system certification that ensures a company can consistently provide products and services that meet customer and regulatory requirements. It is not a product quality certification but focuses on the organization's processes.

What are the Environmental Requirements for Printing Workshops?

Printing workshops should maintain a clean, dust-free environment with a temperature of 23±3°C and a relative humidity of 50±10%.

What is Green Printing?

Green printing refers to environmentally friendly printing practices that use sustainable materials, reduce waste, and minimize pollution throughout the product lifecycle.

---

4. Advanced Printing Techniques

Lamination Options:

- Matte and Gloss Lamination : Standard options for protecting printed surfaces.

- Soft Touch Lamination : Provides a velvety, tactile finish with enhanced scratch resistance.

- Scratch-Resistant Lamination : Offers superior protection against scratches and abrasions.

Color Matching with Spectrophotometers:

For general products, a ∆E* value of ≤2.5 is acceptable, while for high-precision products, ∆E* should be ≤2. This ensures color consistency across different print runs.

Binding Techniques:

- Saddle Stitching : Ideal for booklets with fewer pages.

- Perfect Binding : Common for paperback books.

- Hardcover Binding : Used for premium books and albums.

---

5. Pricing and Order Quantities

Printing costs are influenced by order quantities due to fixed costs like plate making and machine setup. Economical order quantities are typically around 3,000 sheets for offset printing, while flexographic and gravure printing require larger volumes to be cost-effective.

This integrated guide provides a comprehensive overview of printing and packaging, tailored for your target markets. It covers essential topics like paper selection, packaging design, printing processes, and advanced techniques, ensuring your audience has all the information they need to make informed decisions.Let me know if you need further adjustments or additional sections!