Corrugated boxes are a good choice for shipping. They are strong and keep your things safe. These boxes have layers with a wavy middle part. Tests like the Box Compression Test and Edge Crush Test show they stay strong under weight. The boxes are light, so you pay less for shipping. You can pick different flute types for more strength or to stop things from poking through.

Key Takeaways

Corrugated boxes have layers with a wavy part in the middle. This design makes them strong and helps protect things when shipping. These boxes are light, so shipping costs less and they are easy to move. There are different types of corrugated boxes. Some have one wall, some have two, and some have three. Each type has a different strength for light or heavy things. Corrugated boxes are good for the environment. They use recycled materials and can be recycled again. This helps save trees and lowers pollution. You can change the size, printing, and features of corrugated boxes. This helps your product fit well and makes your brand look better. Packing, sealing, and adding soft materials inside keeps breakable things safe. This stops damage when moving the boxes. Corrugated boxes are better than cardboard, plastic, and wood in many ways. They are stronger, cost less, and are better for the planet. Watch out for water and size limits. Use water-resistant coatings and pick the right box strength for your product’s weight and how easy it is to break.

Corrugated Boxes Overview

Corrugated shipping boxes are used all over the world. You can find them in stores, warehouses, and at your home. They arrive when you get a package. What makes them special compared to regular cardboard boxes? It is because of how they are made and their structure.

Structure

Corrugated boxes have a special design. This design gives them both strength and flexibility. They are not just flat cardboard. These boxes have layers that help protect what is inside.

Fluted Layer

The fluted layer is the wavy part inside the box. It sits between two flat sheets. The flutes work like tiny arches. They make the box strong and help it handle pressure from many sides. The fluted layer also helps absorb shocks and bumps. This is important during shipping. There are different flute sizes. Each size gives a mix of strength and softness.

Liners

Liners are the flat sheets on each side of the fluted layer. You see one liner inside and one outside the box. Some boxes have more liners for extra strength. Liners make the box smooth for printing and labels. They also help the box last longer.

Tip: Fluted layers and liners together make corrugated shipping boxes different from regular cardboard. Regular cardboard is just one flat sheet. It does not protect as well.

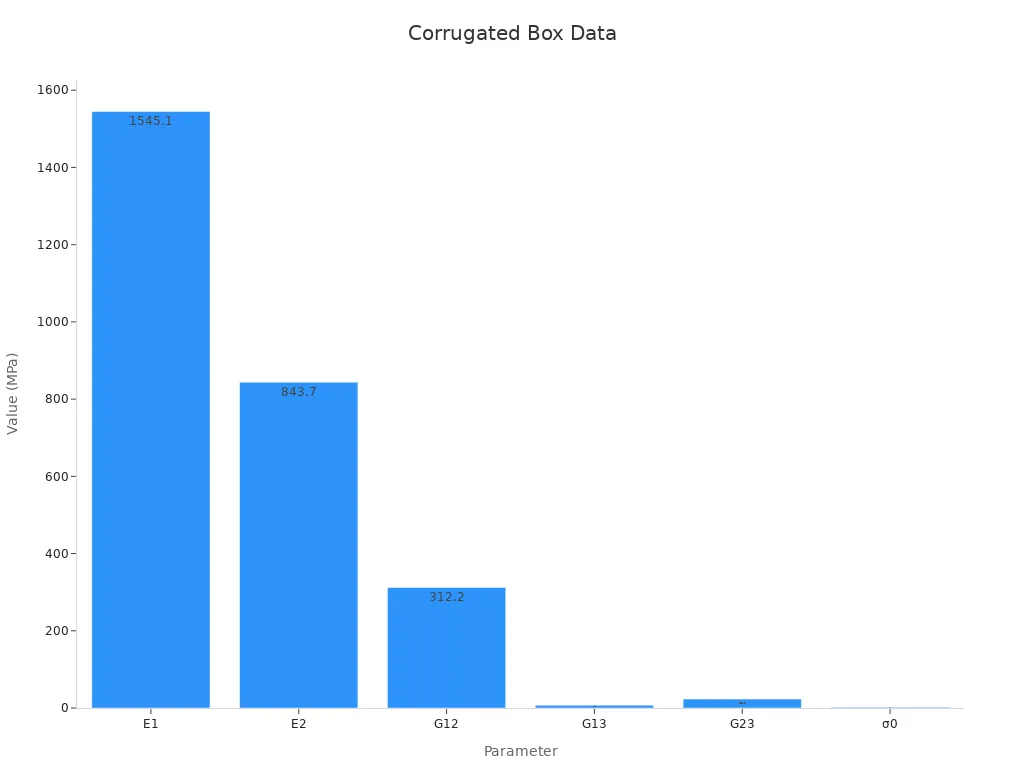

Here is a table with some details about the materials in corrugated boxes:

These numbers show how strong and flexible the material is.

Types

There are different types of corrugated shipping boxes. You can pick the type based on what you need to ship.

Single Wall

Single wall boxes have one fluted layer and two liners. These are the most common type. They are good for light or medium-weight things. About 65% of all shipments use single wall corrugated boxes. They are cheap and easy to use.

Double Wall

Double wall boxes have two fluted layers and three liners. Use these boxes when you need more strength. They are best for heavy things or items that need more protection.

Triple Wall

Triple wall boxes have three fluted layers and four liners. These are the strongest boxes. They are used for very heavy or big things, like machines or large appliances.

Corrugated boxes make up over 80% of all paper shipping packaging in the world.

More than 30% of corrugated boxes are used for food and drinks.

Lighter designs have made boxes up to 15% lighter, which saves money on shipping.

Corrugated shipping boxes can lower shipping costs by 20-25% because they are light and strong.

In 2023, over 180 billion single-wall corrugated boxes were made worldwide.

Note: Tests like the Edge Crush Test and Box Compression Test check how strong these boxes are. These tests help keep your things safe when they are shipped.

Benefits of Corrugated Boxes

Lightweight

Corrugated shipping boxes are much lighter than many other boxes. This makes them easy to carry and move around. You can stack them without much trouble. Lighter boxes help you save money on shipping. Reports say that more people want lightweight corrugated boxes. This is because they use less material and are better for the planet. The Fibre Box Association says corrugated packaging is used the most for shipping. Being light helps businesses and people pay less for shipping. The IMARC Group says new technology makes these boxes even lighter and stronger. This means you get better boxes and save more money.

Tip: Using lightweight corrugated shipping boxes can help you spend less on shipping and make your packages easier to move.

Strength

Corrugated shipping boxes are known for being strong. You can count on them to protect your things. Many tests show how tough these boxes are. The Edge Crush Test and Box Compression Test check how much weight a box can take. These tests prove that corrugated shipping boxes can hold heavy things without breaking. Engineers use computers to test box designs before making them. These computer tests are very close to real life. This means you can trust the strength of these boxes. The fluted layer inside the box also helps make it strong. Some boxes have one or two waves for extra support. You can choose the right box for what you need to ship.

Edge Crush Test and Box Compression Test check how much weight a box can take.

Computer tests help check box strength before making them.

McKee's Formula helps guess how strong a box will be.

Special material tests show how the box acts under stress.

Tests compare wave types to find the best strength for each job.

Protection

You want your things to get there safely. Corrugated shipping boxes give great protection when you ship items. These boxes go through many tests to make sure your things stay safe. Material strength tests like the Ring Crush Test, Edge Crush Test, Bursting Strength, and Puncture Resistance check how tough the box is. Finished box tests like the Box Compression Test, Drop Test, and Inclined Impact Test show how well the box handles drops and bumps. Other tests, like the Spray Test, check if the box keeps out water. All these tests show that corrugated shipping boxes can handle rough shipping and keep your things safe from harm.

Material strength tests check how tough the box is.

Finished box tests show how the box handles real shipping problems.

Environmental tests make sure the box keeps out water.

Note: When you pick corrugated shipping boxes, your things have a better chance of arriving safe and sound.

Cost-Effective

You want to spend less money when you ship things. Corrugated shipping boxes help you save money. These boxes are cheaper to make than many other packages. Factories use less material because the design is strong and light. You do not pay more for heavy boxes. Shipping companies charge by weight. Lighter boxes mean you pay less to ship.

Corrugated shipping boxes also help stop damage. If your things arrive safe, you do not pay for returns or new items. This saves you even more money. Many companies pick these boxes to lower packaging and shipping costs.

Tip: If you ship many things, using corrugated shipping boxes can help your business save thousands of dollars every year.

Customizable

Every item is different. Corrugated shipping boxes can fit almost any shape or size. You can order boxes that match your product’s size. This means you do not waste space or use extra packing. You can pick different wall thicknesses for more safety.

You can print your logo or directions on the box. This helps people notice your brand. Some companies add handles, dividers, or windows. These features make packing and unpacking easier.

Custom sizes fit your things better.

Printing helps with branding and directions.

Special features make boxes easier to use.

Corrugated shipping boxes give you many ways to make your packaging work for you.

Eco-Friendly

You want to help the planet. Corrugated shipping boxes support your green goals. Most of these boxes come from recycled paper. Factories use less water and energy to make them. When you finish using a box, you can recycle it again.

A recent study shows big changes in the environmental impact of corrugated boxes. From 2006 to 2020, greenhouse gas emissions per box dropped by half. Other impacts, like energy use, water use, and air pollution, also went down. These changes happened because of better recycling, cleaner energy, and smart forest care.

Studies also show that corrugated boxes are better for the environment than many plastic boxes. They use less water and energy to make and recycle. You help the earth every time you pick corrugated shipping boxes.

Note: Recycling corrugated shipping boxes is easy. Most recycling centers take them, so you can keep them out of landfills.

Reusable

You can use corrugated shipping boxes more than once. This helps you save money and protect the planet. Many companies use reusable packaging to cut costs and waste.

General Motors saved $12 million in five years. They used reusable containers and pallets many times. This lowered their disposal costs.

Ford stopped throwing away 30,000 pounds of waste each day. They used only reusable containers for parts. This helped them pay less for waste removal.

DaimlerChrysler used a small-lot container program. They saw a 60% drop in assembly line inventory. They needed less storage space and handled fewer parts.

A large truck maker used right-sized reusable containers. This helped them use space better and store less inventory.

Reusable packaging does more than save money. You can stack these boxes higher and fit more in each shipment. This means you need fewer trips to move products. Fewer trips lower your transportation costs. Using the same boxes again means you buy less new packaging. You also save time because you do not clean up broken boxes or extra trash.

Tip: Reusing corrugated shipping boxes helps protect your products. It cuts down on waste and makes shipping easier.

Reusable boxes are strong and last a long time. They keep your items safe through many trips. You can use them for different products or shipments. This makes them a smart investment for your business.

Some reusable packaging helps keep workers safe. Ergonomic designs make boxes easier to handle. This lowers the chance of injury. Boxes with the same size help machines work better and stop jams. Strong boxes also lower the risk of product damage. You lose fewer items during shipping.

If you want to save money and help the earth, pick reusable corrugated shipping boxes. You will see the benefits in your budget and daily work.

Corrugated Boxes vs. Other Packaging

When you pick packaging for shipping, you have choices. Each type has good and bad points. Let’s see how corrugated shipping boxes compare to cardboard, plastic, and wood.

Cardboard

Some people think cardboard and corrugated shipping boxes are the same. They are not the same. Cardboard is just one flat layer. Corrugated shipping boxes have three layers. There are two flat liners and a wavy middle. This makes them much stronger.

Corrugated shipping boxes keep your things safe from bumps. The wavy layer works like a cushion.

Cardboard is best for light things or as inserts. It does not do well in rough shipping.

Corrugated shipping boxes handle water better than cardboard. This keeps your things safer.

You can change corrugated shipping boxes in thickness, coatings, and size. Cardboard cannot do this.

Corrugated shipping boxes are light and strong, so shipping costs less. Cardboard may seem cheap, but it can cause more damage and cost more to replace.

Over 75% of online orders use corrugated shipping boxes. They are strong, light, and save money.

Plastic

Plastic packaging is used a lot, but it has problems. Plastic boxes last a long time, but they are not always best for shipping.

Corrugated shipping boxes are made from recycled materials. They can be recycled or composted. Plastic takes a very long time to break down.

Making corrugated shipping boxes uses less energy than plastic. It also makes less pollution.

Corrugated shipping boxes do not have harmful chemicals. Plastic often has chemicals that hurt the environment.

Corrugated shipping boxes save you money. They ship flat, so storage and transport cost less.

Many companies now use corrugated shipping boxes to follow new recycling laws.

Corrugated shipping boxes break down in about 60 days. Plastic can take up to 500 years.

Wood

Wooden packaging is strong, but it is heavy and not easy to use. You might use wood for big or heavy things, but it has problems.

Corrugated shipping boxes have many benefits over wood. They are lighter and easier to use. They are also better for the earth. You do not have to worry about import rules like with wood.

Tip: If you want to save money and help the earth, corrugated shipping boxes are a smart pick.

Drawbacks

Moisture Sensitivity

Corrugated shipping boxes do not handle water well. If you leave them in a damp place, they can get soft and lose their strength. Rain, spills, or high humidity can weaken the box. When the box gets wet, the fluted layer inside absorbs water. This makes the box bend or even fall apart. You might see the box sag or tear if it gets too wet.

You can use special coatings or liners to help protect the box from moisture. Waxed or laminated boxes work better in wet places. Still, these options cost more and may not be as easy to recycle. If you ship food, drinks, or items that need to stay dry, you must think about moisture. Always store your boxes in a dry area and keep them away from water.

Tip: If you expect rain or high humidity, pick boxes with water-resistant coatings or use plastic wrap for extra safety.

Tape Usage

You need tape to seal corrugated shipping boxes. The fluted layer and liners make the box strong, but the flaps need tape to stay closed. If you use too little tape, the box can open during shipping. This puts your items at risk. You may need to use more tape for heavy or large boxes.

Some people use glue or staples, but tape is the most common choice. Using more tape adds to your packing time and cost. You also need to pick the right kind of tape. Cheap tape may not stick well, especially if the box is dusty or cold. Strong packing tape works best for most shipments.

Use at least three strips of tape: one down the middle and one on each edge.

For heavy boxes, use extra tape on the bottom.

Reinforced tape helps with very heavy or valuable items.

Note: Good taping keeps your box closed and your items safe. Do not skip this step.

Size Limits

Corrugated shipping boxes come in many sizes, but there are limits. Very large boxes can be hard to handle and may not stay strong. If you pack too much weight, the box can crush or break. Shipping companies also have size and weight rules. Oversized boxes cost more to ship and may not fit on standard trucks or shelves.

Box strength depends on tests like the Edge Crush Test (ECT), Bursting Strength, and Box Compression Test. These tests show how much weight and pressure a box can take. Bigger boxes need higher ECT and bursting strength values to keep your items safe. If you use a box that is too big or too weak, your products can get damaged.

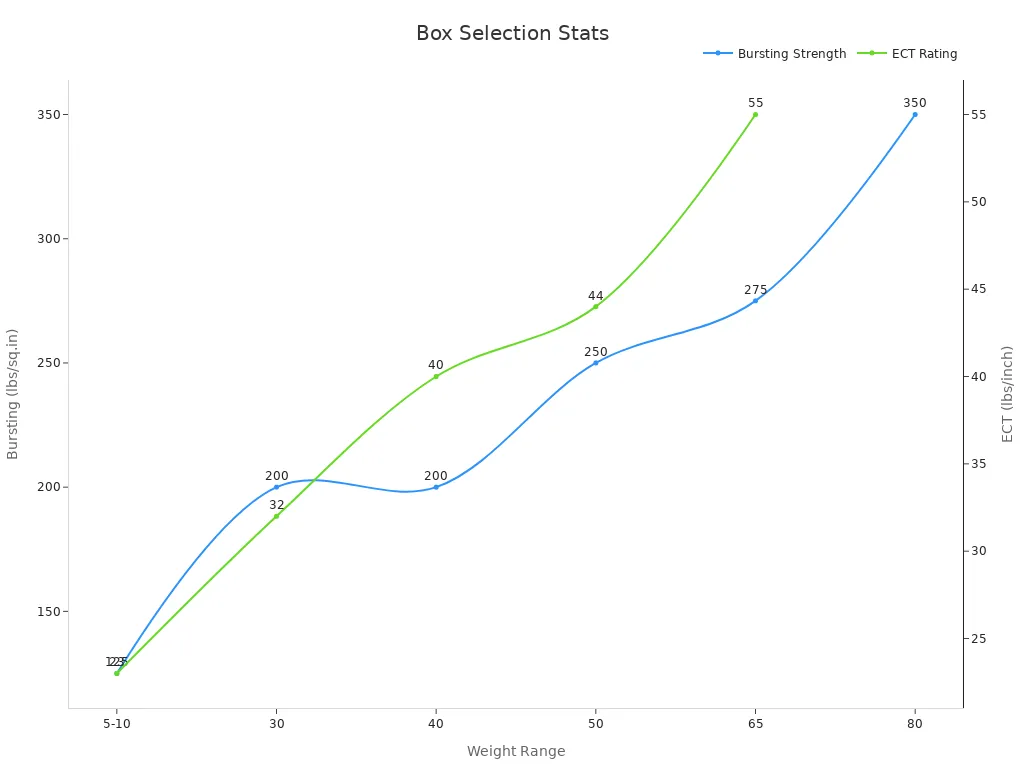

Here is a table that shows how box size and strength affect shipping:

You must match the box size and strength to your product. If you ship heavy or large items, pick boxes with higher ECT and thicker flutes. This keeps your products safe and helps you avoid extra shipping costs.

Tip: Always check the weight and size limits before you choose a box. The right size and strength protect your items and save you money.

Not for All Products

Corrugated shipping boxes are good for many things, but not all. Some products need more protection or special packaging. You should know when these boxes are not the best choice.

1. Heavy Machinery and Industrial Equipment

Very heavy machines or tools can crush these boxes. Corrugated shipping boxes may tear under a lot of weight. Wood or metal crates are better for these items. These materials hold up under more pressure and keep things safe.

2. Liquids and Wet Goods

Liquids can spill or leak during shipping. Corrugated shipping boxes soak up water and get weak when wet. Even with coatings, water can still hurt the box. Glass bottles or chemicals need waterproof packaging. Plastic or metal containers work better for these items.

3. Sharp or Pointed Items

Sharp tools or metal rods can poke through the box walls. The fluted layer helps, but sharp edges may still break through. Use reinforced packaging or extra padding for these things. Sometimes, plastic or wooden boxes are safer for sharp items.

4. High-Value or Fragile Electronics

Electronics like laptops or tablets need extra care. Corrugated shipping boxes protect from bumps, but not from static or water. Sensitive electronics need anti-static bags or foam inserts. Hard cases are also a good choice for these products.

5. Temperature-Sensitive Goods

Some things must stay cold or hot. Corrugated shipping boxes do not keep the right temperature. Ice cream or vaccines can spoil if the box does not insulate well. Use insulated containers or coolers for these shipments.

Tip: Always pick packaging that fits your product’s needs. If your items need special care, choose packaging with extra features.

Here is a simple table to help you choose:

Think about your product’s weight, shape, and special needs. Corrugated shipping boxes work for most things, but not everything. If you are not sure, ask a packaging expert or try different options.

Choosing Corrugated Boxes

Product Weight

When you choose a shipping box, you need to think about how much your product weighs. Heavier items need stronger boxes. Lighter products can use boxes with lower strength. You can use tests like the Edge Crush Test (ECT) and the Bursting Strength Test to check how much weight a box can handle. These tests help you pick the right box for your needs.

Here is a table that shows how product weight matches with box strength:

You can see that as the weight goes up, the box needs a higher ECT and bursting strength. This helps keep your items safe during shipping. If you use a box that is too weak, it may crush or break.

The ECT rating tells you how much weight the box can take on its edge. Flute type also matters. C flute gives a good mix of strength and cushioning. B flute is thinner but resists crushing well. Picking the right ECT and flute type helps your box handle the weight and shipping conditions.

Tip: Always check your product’s weight before picking a box. This helps you avoid damage and extra shipping costs.

Fragility

You also need to think about how fragile your product is. Fragile items need more protection. You should look for boxes with higher ECT or bursting strength ratings. These ratings show how much force the box can take before it crushes or bursts.

Product fragility and weight both affect your box choice.

ECT measures stacking strength. It works well for lighter, stackable items like books or clothes.

The Mullen Test (bursting strength) checks if the box can resist bursting. This is important for heavy or fragile things like glass or electronics.

32 ECT boxes are good for items with moderate fragility. They are light and cost less.

200# Mullen-rated boxes are best for heavy or very fragile products.

If you use a box that is too strong for a light item, you pay more for shipping without extra safety. If you use a weak box for a fragile item, you risk damage. UPS and other shipping companies suggest matching box strength to both weight and fragility.

Here are some steps to protect fragile items:

Pick boxes with high burst strength or ECT ratings.

Use double-wall boxes for very fragile or valuable items.

Wrap each item with bubble wrap or foam.

Add padding inside the box to stop movement.

Fill empty spaces with packing material.

Seal the box well with strong tape.

Mark the box as 'Fragile' so handlers know to be careful.

Note: Choosing the right box strength for fragile items keeps your products safe and saves money.

Shipping Distance

Shipping distance also affects your box choice. If you ship items far away, your box faces more bumps and handling. Long trips mean more chances for damage. You should use stronger boxes for longer distances.

Short trips may not need the strongest box. For local deliveries, a single-wall box with a lower ECT rating may work. For cross-country or international shipping, pick boxes with higher ECT and bursting strength. Double-wall boxes give extra safety for long journeys.

Think about the shipping route. If your package will be stacked or moved many times, use a box that can handle the pressure. Stronger boxes help your items arrive safely, even after a long trip.

Tip: For long-distance shipping, always choose a box with higher strength ratings. This helps your products survive the journey.

Wall Type

You need to choose the right wall type for your shipping needs. Wall type means how many layers of fluting and liners the box has. Each wall type gives a different level of strength and protection.

Single-wall boxes have one layer of fluting between two liners. You can use these for light or non-fragile items. They are light and cost less, but they do not protect heavy or delicate products well.

Double-wall boxes have two layers of fluting and three liners. These boxes give more strength and cushioning. You should use double-wall boxes for heavier or fragile items like electronics or appliances. They help protect your products from bumps and drops during shipping.

Triple-wall boxes have three layers of fluting and four liners. These boxes are the strongest. You can use them for very heavy or bulky products. Industries like aerospace and manufacturing often use triple-wall boxes for their toughest shipping jobs.

The choice of wall type depends on your product’s weight, fragility, and how much protection you need during shipping and storage. Picking the right wall type helps keep your items safe and lowers the risk of damage.

Size

You must pick the right size for your corrugated shipping boxes. The size of the box affects how well it protects your product. If the box is too big, your items can move around and get damaged. If the box is too small, it may crush your product or not close properly.

Researchers tested 240 different box models with different sizes and shapes. They found that box size and shape change how much weight a box can hold.

Boxes with holes or perforations lose some strength. The loss can be from 14.5% to 45%, depending on where and how big the holes are.

For boxes with a base ratio of 3:2 and heights from 200 to 300 mm, the average strength loss was about 26%.

Cubic boxes with heights from 250 mm to 450 mm lost between 18.8% and 45% of their strength, but bigger boxes lost a smaller percent.

The McKee formula and compression tests help you know how box size and changes affect strength.

You should match the box size to your product. Leave just enough space for padding. This helps keep your items safe and lowers the chance of damage during shipping.

Tip: Always check the size and shape of your product before picking a box. The right size keeps your items safe and saves money on shipping.

Special Features

You can add special features to corrugated shipping boxes to fit your shipping needs. These features help protect your products and make shipping easier.

BC flute cardboard is thick and strong. You can add foam inserts for extra cushioning. This works well for heavy or delicate items.

Triple-wall boxes give the most protection. They pass tough edge crush tests and work well for glassware or electronics.

Full Overlap Container (FOL) boxes have flaps that cover the whole top. This gives extra strength for heavy or fragile items and for long trips.

Double-wall and triple-wall boxes add more layers for extra strength. You can use these for heavy or bulky products.

Partitions and dividers inside the box keep items apart. This stops them from moving and breaking, which is good for glass bottles or other fragile goods.

Custom designs, like bright colors or special messages, can make your packaging stand out. Some brands use recycled materials to attract eco-friendly customers.

Custom boxes can lower product damage, reduce returns, and save money over time. They also help with marketing by showing your brand and giving customers a better experience.

Note: Adding special features to your boxes can protect your products, improve customer satisfaction, and help your business grow.

Packing Tips

Assembly

You want to start with the right assembly steps for corrugated shipping boxes. First, unfold the box and make sure all the creases are sharp. Push the bottom flaps inward and fold them down one by one. Press the corners to keep the box square. This helps the box hold its shape and strength.

Many corrugated shipping boxes now use fast-assembly designs. These boxes pop into shape quickly. Some even have self-sealing strips, so you do not need extra tape or glue. Fast-assembly boxes save you time and effort, especially if you pack many boxes each day. E-commerce businesses and shipping centers use these boxes to speed up their work.

Customized die-cut corrugated shipping boxes also help with assembly. These boxes fit your products perfectly. You do not need to use much filler or extra tape. They fold flat for storage, so you save space in your stockroom. When you need them, you can set them up fast and pack your items right away.

Tip: Choose fast-assembly or die-cut corrugated shipping boxes if you want to pack quickly and use less packing material.

Sealing

Sealing your corrugated shipping boxes the right way keeps your items safe. Start by folding the top flaps down after you fill the box. Use strong packing tape for the best hold. Place one strip of tape down the center seam. Add strips along both edges for extra strength.

For heavy or valuable items, use reinforced tape. Some boxes come with self-sealing strips. These make sealing even faster and reduce the need for extra tape. Always press the tape down firmly to make sure it sticks well.

If you use glue or staples, check that they hold the flaps tight. Do not leave gaps or loose edges. A well-sealed box protects your products from dust, dirt, and moisture during shipping.

Note: Good sealing prevents the box from opening during transport. This lowers the risk of damage or loss.

Cushioning

Cushioning is what keeps your items safe inside corrugated shipping boxes. You want to stop your products from moving or breaking during shipping. Use bubble wrap, foam inserts, or air pillows to fill empty spaces. For fragile items, wrap each piece before placing it in the box.

You can also use inner supports made from wood or extra corrugated board. These supports add strength and help absorb shocks. Thicker corrugated shipping boxes with larger flutes trap more air. This gives better shock absorption and protects your items from bumps.

Tests like the Edge Crush Test (ECT), Bursting Strength Test, and Box Compression Test show how well a box can handle stacking, pressure, and rough handling. The Puncture Resistance Test checks if the box can withstand sharp objects. The Flat Crush Test measures how much pressure the flutes can take before collapsing. All these tests prove that good cushioning and strong boxes work together to protect your products.

Tip: Always use enough cushioning to keep your items from shifting. This helps your corrugated shipping boxes do their job and deliver your products safely.

Labeling

Labeling plays a big role when you ship products in corrugated shipping boxes. You want your packages to reach the right place, stay safe, and follow shipping rules. Good labeling helps you avoid lost packages, delays, or damage.

What is labeling for corrugated shipping boxes?

Labeling means putting important information on the outside of your box. This information tells handlers, shippers, and customers what is inside, where it should go, and how to treat the package. You use labels, stickers, or printed text for this purpose.

What should you include on your labels?

You need to make sure your labels are clear and easy to read. Here are the main things you should put on your corrugated shipping boxes:

Shipping address: Write the full address of the person or business receiving the package.

Return address: Add your own address in case the package needs to come back.

Handling instructions: Use words like "Fragile," "This Side Up," or "Handle With Care" if needed.

Barcodes or tracking numbers: These help shipping companies scan and track your box.

Contents description: Write what is inside if shipping rules require it.

Hazard warnings: If your box has dangerous items, use the right warning labels.

Tip: Always use waterproof labels or cover them with clear tape. This keeps the information safe if the box gets wet.

What are the best practices for labeling corrugated shipping boxes?

Place labels on the largest, flattest side. This makes them easy to see and scan.

Use large, bold text. Handlers can read the information quickly.

Avoid placing labels over seams or tape. Labels stick better on smooth surfaces.

Double-check all information. Make sure addresses and numbers are correct.

Add extra labels for special handling. Use arrows or symbols if your box must stay upright.

Sample Label Placement Table:

You want your corrugated shipping boxes to arrive safely and on time. Good labeling helps everyone in the shipping process do their job right. When you follow these steps, you lower the risk of lost or damaged packages. You also make your business look more professional.

Note: If you ship many boxes, consider using printed labels or a label printer. This saves time and reduces mistakes.

Labeling is not just about sticking a sticker on a box. It is about making sure your corrugated shipping boxes get where they need to go, in the best condition possible.

Sustainability

Recycling

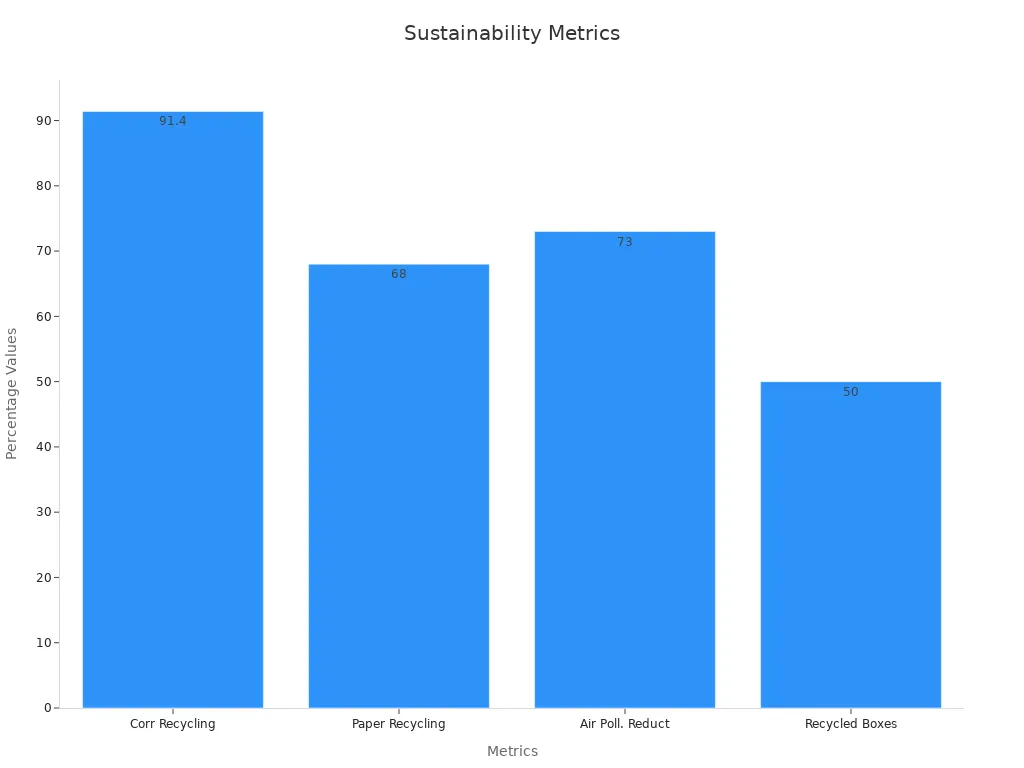

When you recycle corrugated shipping boxes, you help the earth. These boxes are recycled more than most other packaging. In the United States, about 91.4% of corrugated cardboard gets recycled. This is much higher than the 68% recycling rate for all paper products. Recycling one tonne of corrugated shipping boxes saves 17 trees. It also saves 380 gallons of oil and 7,000 gallons of water. Recycling keeps trash out of landfills. Each year, recycling these boxes keeps enough waste out of landfills to fill over 100,000 double-decker buses. Factories that use recycled paper make 73% less air pollution than those using new paper.

Here is a table that shows how recycling corrugated shipping boxes helps the planet:

Tip: Always flatten your corrugated shipping boxes before recycling. This easy step saves resources and helps the environment.

Recycled Materials

Corrugated shipping boxes are often made with recycled paper. Almost half of all recycled paper is used to make new boxes. This helps create a circular economy. You use a box, recycle it, and it becomes a new box. Using recycled materials means factories cut down fewer trees. This helps forests and animals.

When you pick corrugated shipping boxes with recycled content, you help save energy and lower pollution. Factories that use recycled fibers need less water and oil. They also make less waste. Many companies now use better recycling systems and new machines. These changes make it easier to use recycled materials in every box.

Choosing boxes with recycled content shows you care about the earth and want to help.

Trends

More people and businesses want eco-friendly packaging. Corrugated shipping boxes are leading this change. The market for these boxes is growing because people want packaging that is good for the planet. Online stores use more corrugated shipping boxes to ship products and cut down on waste. Food and drink brands also use these boxes for safety and cleanliness.

Here are some important trends for corrugated shipping boxes:

The recycling rate for old corrugated containers reached 93.6% in 2022.

Lighter boxes help lower fuel use and carbon emissions during shipping.

New rules in places like the European Union ask for higher recycling rates, up to 85% by 2030.

Companies are building more recycled fiber plants and using new technology to make greener boxes.

Better printing and design let you make custom boxes that are still eco-friendly.

Note: When you choose corrugated shipping boxes, you help make the future cleaner and set new standards for packaging.

Corrugated shipping boxes keep your things safe, help you save money, and are good for the earth. You can change them to fit almost any product you have. Many companies use corrugated shipping boxes because they work well and cost less. There are some problems, like getting weak when wet or costing more for special designs, but you can fix these with coatings or by planning ahead.

Pick the right box for what you need to ship. Corrugated boxes are still a great way to ship things safely and easily.

FAQ

What are corrugated shipping boxes made of?

Corrugated shipping boxes use layers of paperboard. There are two flat liners and a wavy fluted layer in the middle. This design makes the box strong. It helps keep your things safe when you ship them.

What makes corrugated shipping boxes different from regular cardboard?

Corrugated shipping boxes have a fluted layer between the liners. Regular cardboard is just one flat piece. The fluted layer gives more strength. It protects your products better than regular cardboard.

What products work best with corrugated shipping boxes?

You can use corrugated shipping boxes for books, clothes, and electronics. They also work for food and many things at home. These boxes are good for items that need protection from bumps or stacking.

What sizes do corrugated shipping boxes come in?

Corrugated shipping boxes come in many sizes. You can get small, medium, or large boxes. You can also order boxes made to fit your product. This helps you use less space and packing material.

What tests check the strength of corrugated shipping boxes?

You can test box strength with the Edge Crush Test (ECT). The Box Compression Test and Bursting Strength Test also help. These tests show how much weight and pressure the boxes can take.

What should you do if your product is fragile?

Pick corrugated shipping boxes with higher strength ratings. Add bubble wrap or foam for extra cushioning. Mark the box as "Fragile" so people know to be careful.

What happens to corrugated shipping boxes after use?

Most corrugated shipping boxes can be recycled. Many recycling centers will take them. Recycling saves trees, water, and energy. You help the earth when you recycle your boxes.

What are the main benefits of using corrugated shipping boxes?

Corrugated shipping boxes give strong protection and lower shipping costs. They are easy to recycle. You can change them to fit your needs. These boxes help keep your products safe and are good for the planet.